Do you know how to install Road Studs professionally and what to pay attention to?

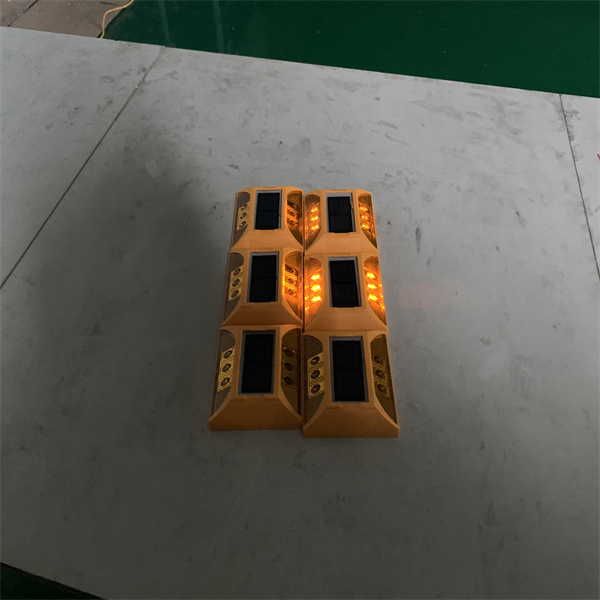

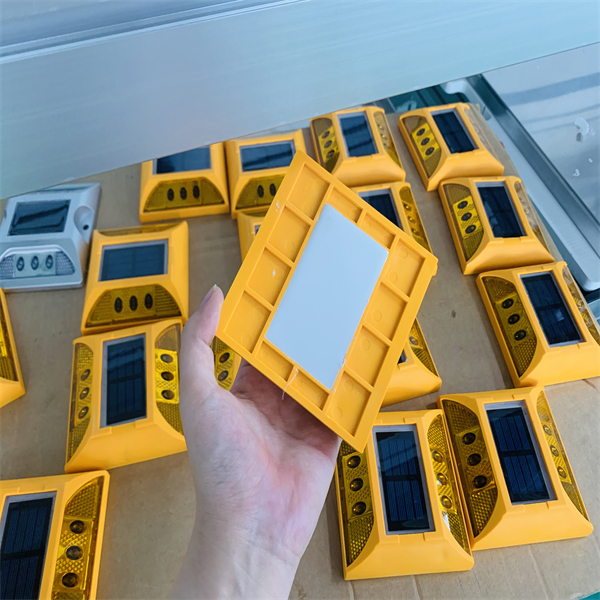

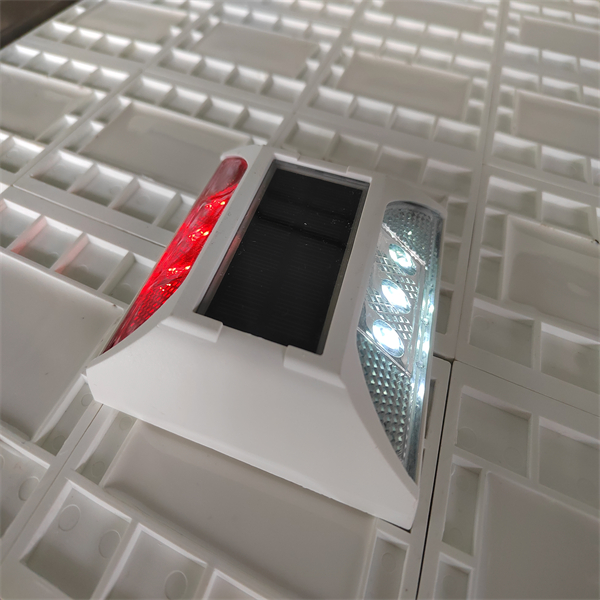

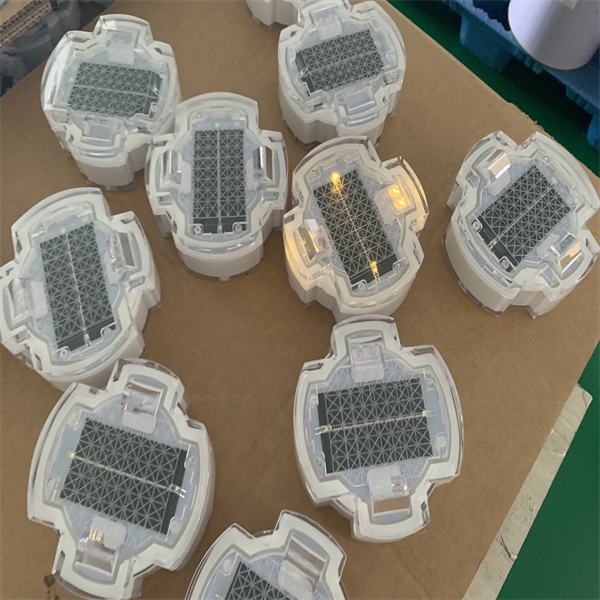

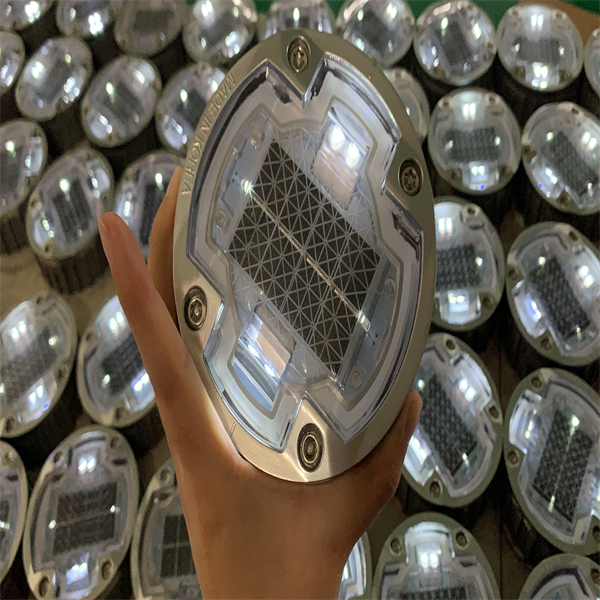

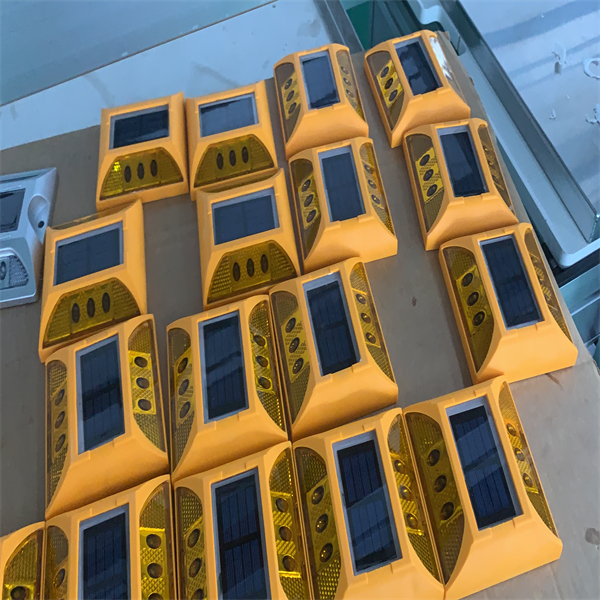

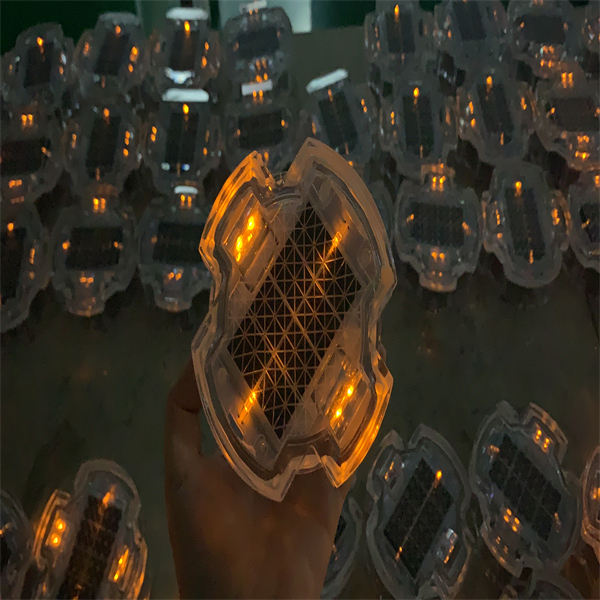

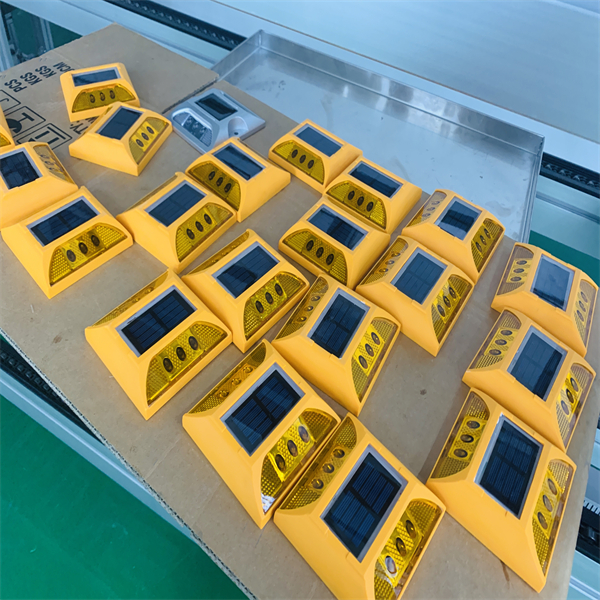

Road Studs mainly refers to a traffic safety facility. Protruding road signs with scientific names are mainly installed in the middle of the road markings or in the middle of the double yellow lines to remind the driver to drive in the lane through its retroreflective performance.

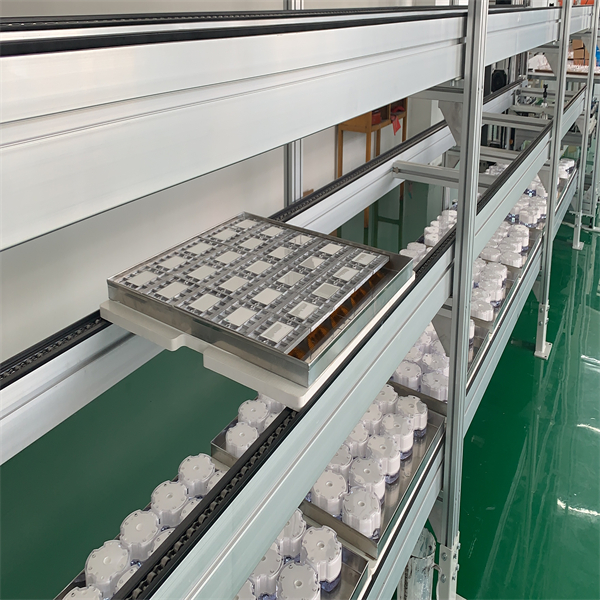

The installation of Road Studs generally adopts epoxy resin installation.

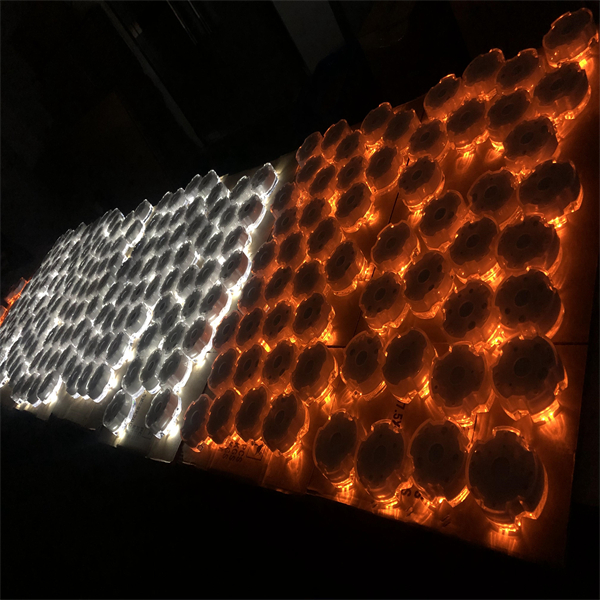

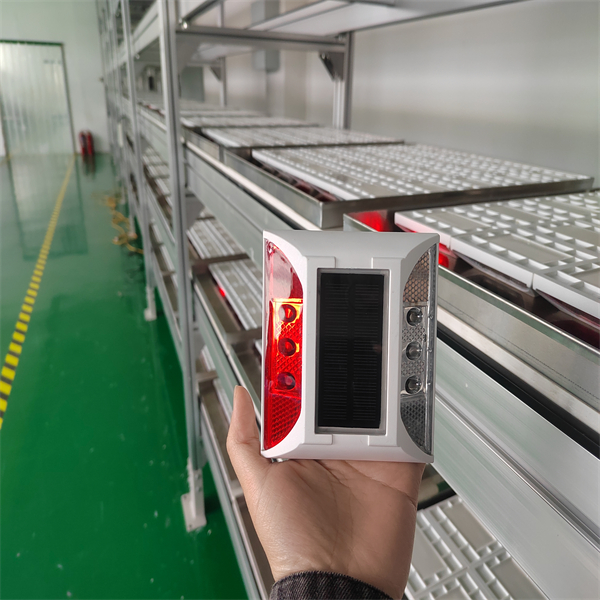

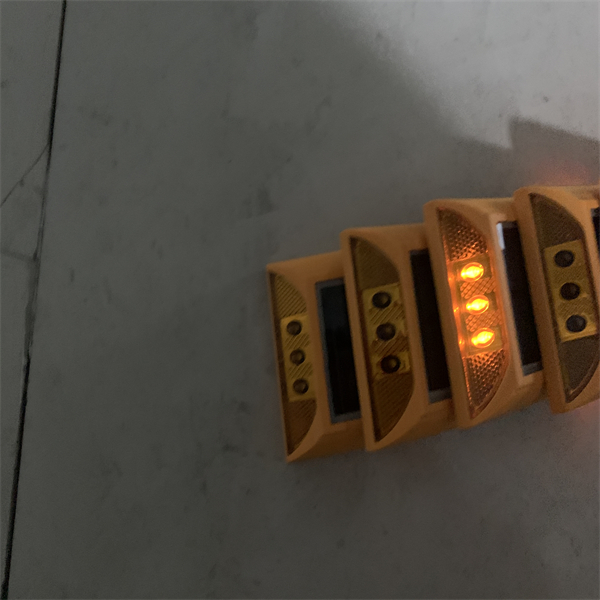

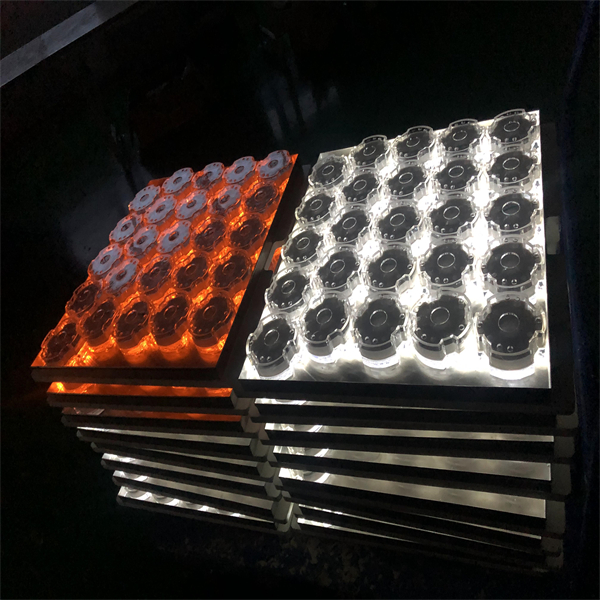

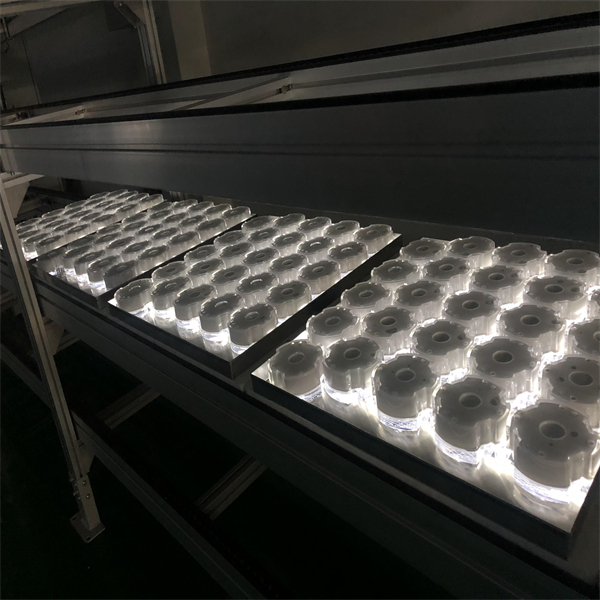

At night, the outline of the road can be clearly drawn with the help of car lights. Play a good visual inducing effect.

Road Studs mainly refers to a traffic safety facility. Protruding road signs with scientific names are mainly installed in the middle of the road markings or in the middle of the double yellow lines to remind the driver to drive in the lane through its retroreflective performance.

The installation of Road Studs generally adopts epoxy resin installation.

At night, the outline of the road can be clearly drawn with the help of car lights. Play a good visual inducing effect.

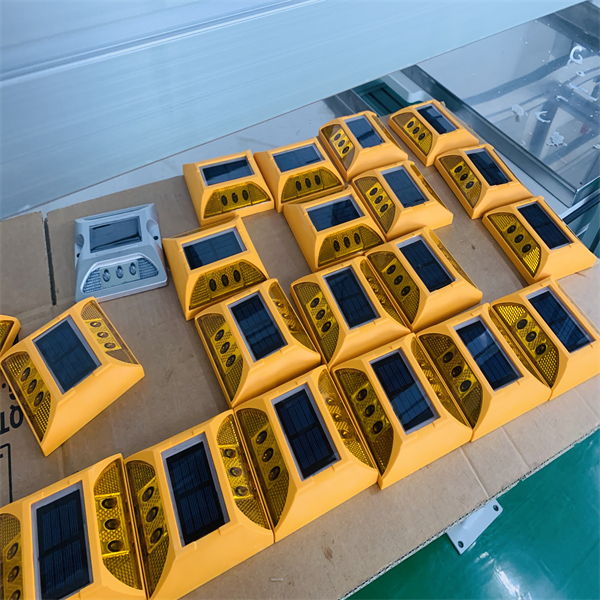

With the wide application of Road Studs in domestic high-grade highways and municipal roads, the quality and service life of Road Studs have received more attention. In the actual application process, the road studs are often damaged and the service life is reduced due to installation problems.

Based on Ruichen Traffic’s years of construction experience, I summarized the problems that often occurred during the installation of Road Studs, and proposed a reasonable installation method. I hope everyone can receive the goods.

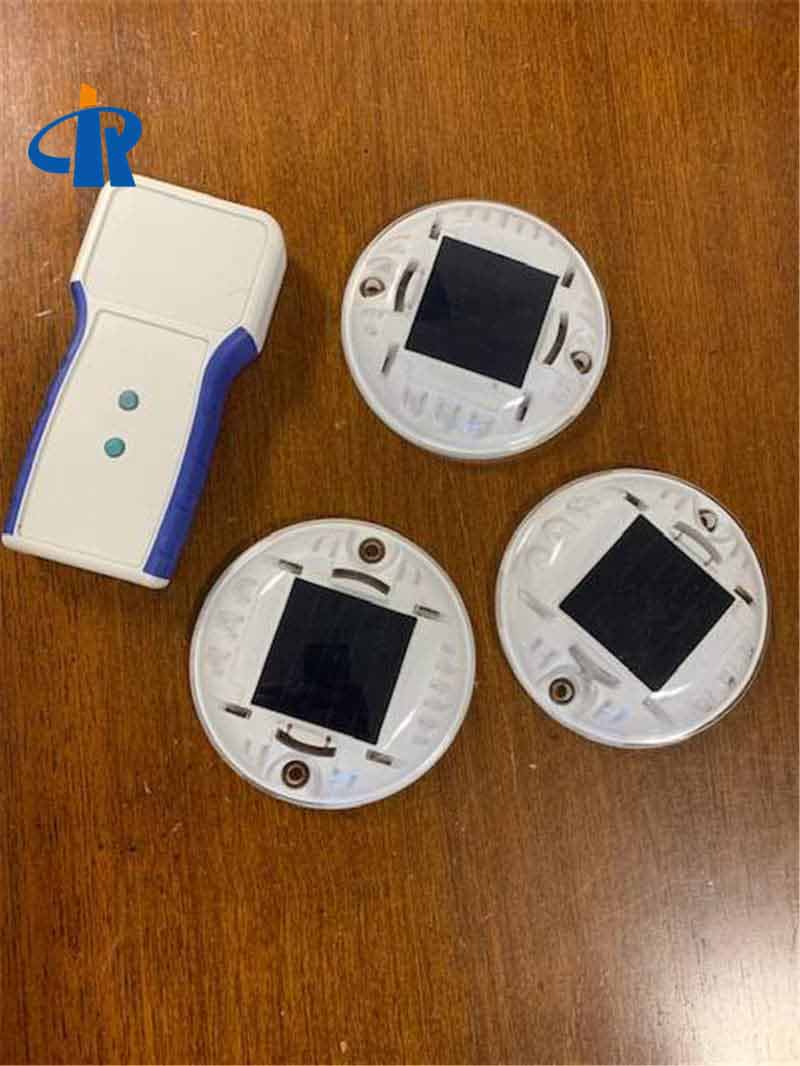

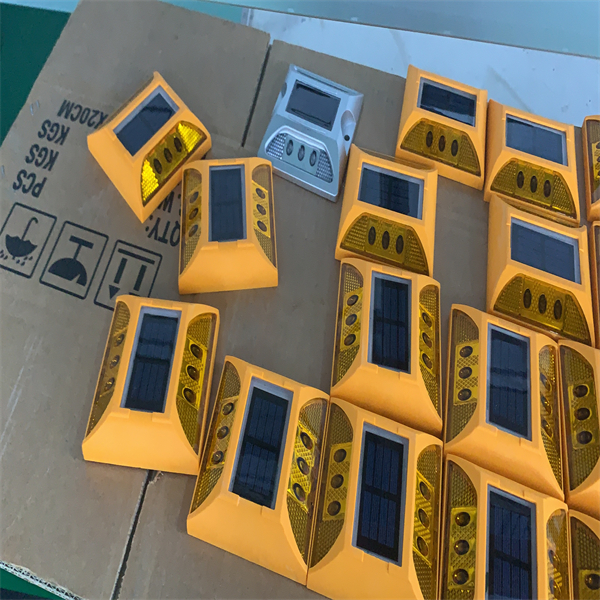

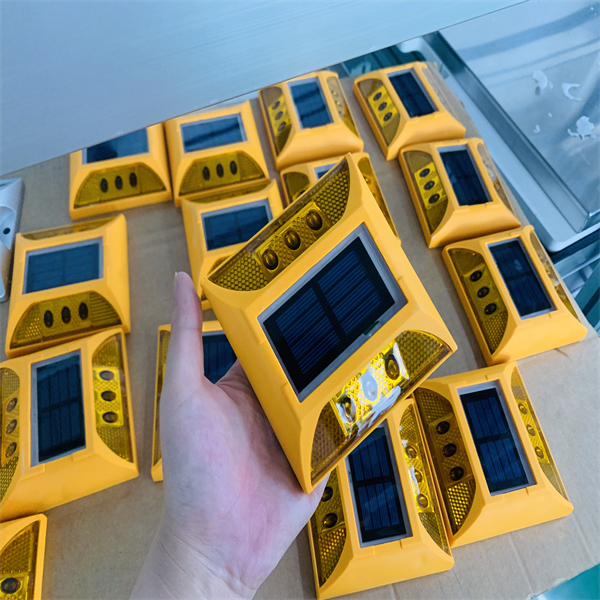

The following are some of the problems that often occur during the installation of Solar Studs:

1. Solar Studs are installed on the marking line.

The marking line is also a kind of resin material, which is attached to the ground, and its connection with the ground has a certain limit. If the Solar Studs is installed on the marking line, the impact force of the Solar Studs is completely transferred to the marking line. In this way, the road stud is easily impacted off, and the marking line will also be glued.

2. The installation location of Solar Studs is uneven.

The direct consequence of is the uneven force on the Solar Studs. The pressure on the Solar Studs is almost concentrated on the convex and concave parts. If you encounter a large-tonnage vehicle, the spike is easy to break.

3. The installation location of Solar Studs is not clean.

The firmness of Solar Studs depends on the close combination of spikes, glue and the ground. If the installation location is not clean, the dust in between will absorb most of the adhesive force of the glue, causing the Solar Studs to be weakly bonded and easy to fall off when subjected to external impact.

4. The amount of installation glue is insufficient or excessive.

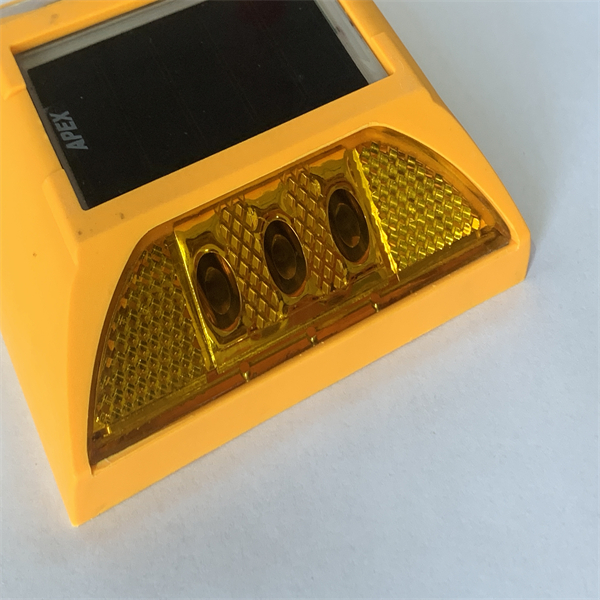

Insufficient dosage will reduce the firmness of Solar Studs bonding and reduce its service life; if the dosage is too much, excess glue will ooze out from around the road stud, and it is easy to rub on the reflective sheet of the road stud, affecting its reflective brightness.

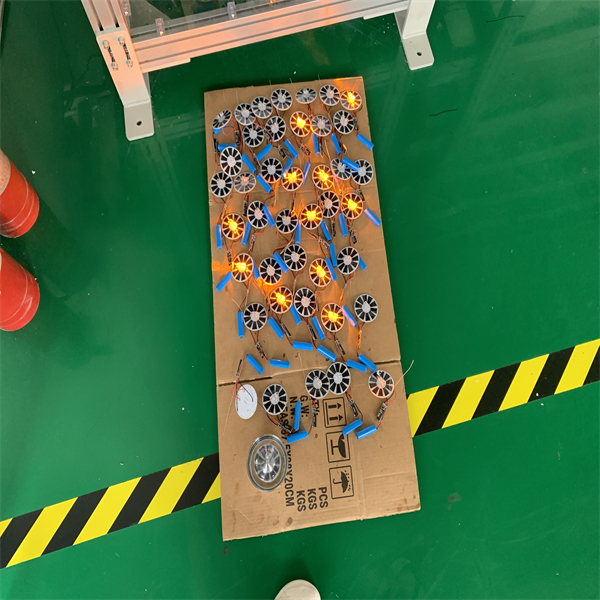

5. Solar Studs installation glue is unevenly applied.

When installing Solar Studs, not only should the amount of glue be appropriate, but also apply evenly, so as to ensure that all parts of the Solar Studs are evenly stressed and avoid being crushed due to uneven force.

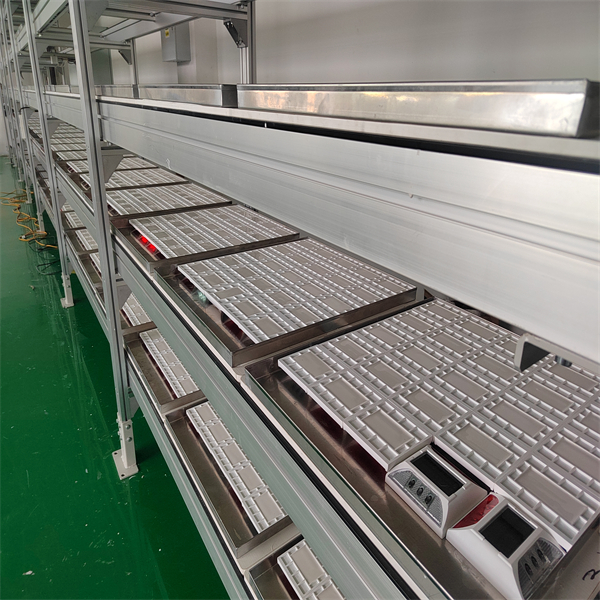

6. The ambient temperature is not enough when installing glue for Solar Road Studs.

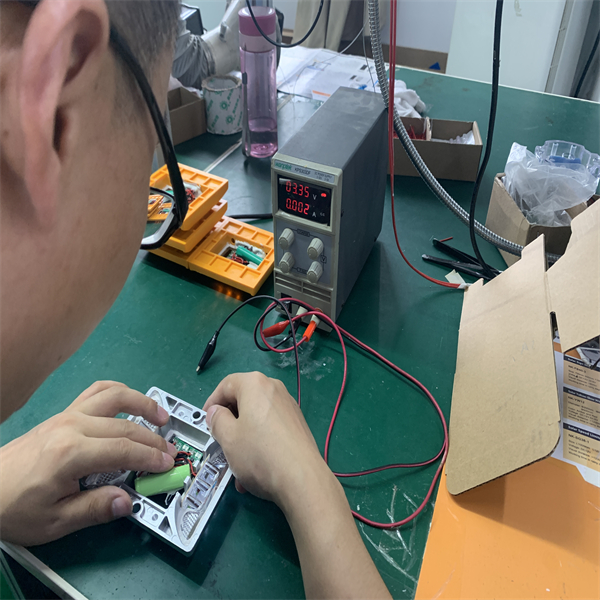

Solar Road Studs installation glue is epoxy resin, it is a two-component glue, glue and curing agent must be proportioned according to a certain ratio, and the effect can only be exerted after uniform mixing. However, because epoxy resin glue condenses more severely in low temperature weather in winter, it is not easy to stir evenly, so it must be heated before use to let the glue soften before use.

7. The method of Solar Road Studs is unscientific.

When holding the Solar Road Studs, be sure to hold the two sides without the reflector, so as not to stick the glue on the reflector and affect the brightness of the reflector.

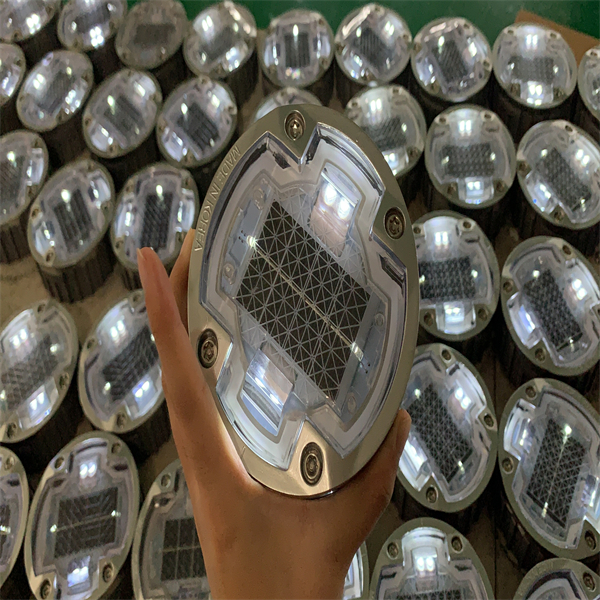

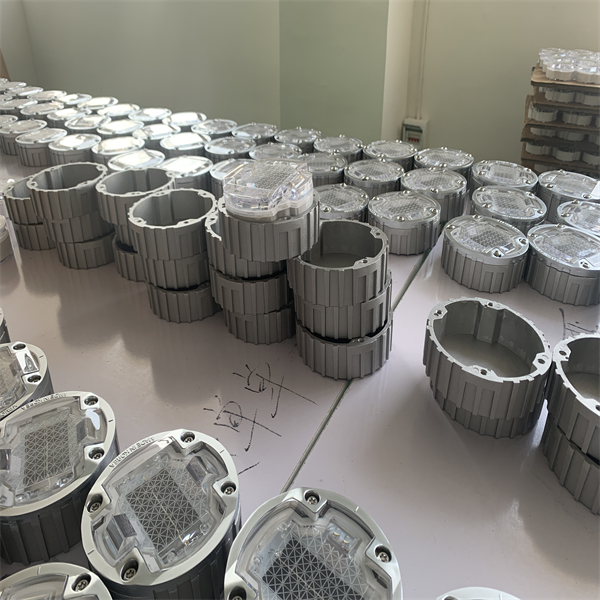

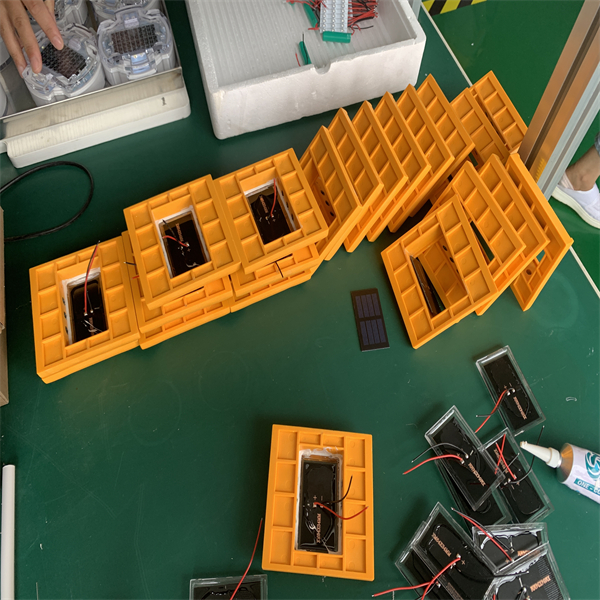

8. The mounting hole is shallow and the hole is fine.

This is mainly for Solar Road Studs with cast aluminum feet. Solar Road Studs with cast aluminum feet have better impact resistance, compression resistance, and longer service life because of their partial penetration into the ground. However, during the installation process, if the hole position is too shallow or too thin, the bottom surface of Solar Road Studs will not be in full contact with the ground, which will affect the firmness of the bonding.

9. The glue curing time is not enough after installation.

After the Solar Road Studs are installed, the glue needs a period of time to solidify to connect the Solar Road Studs to the ground. The recommended period of time is 6-8 hours. But in the actual process, many people remove the installation isolation facilities less than two hours after installation; in this case, if the vehicle is impacted and crushed, the light spike will be deformed, and the heavy spike will fall off.

I hope it can help you choose high-quality Solar Road Studs.