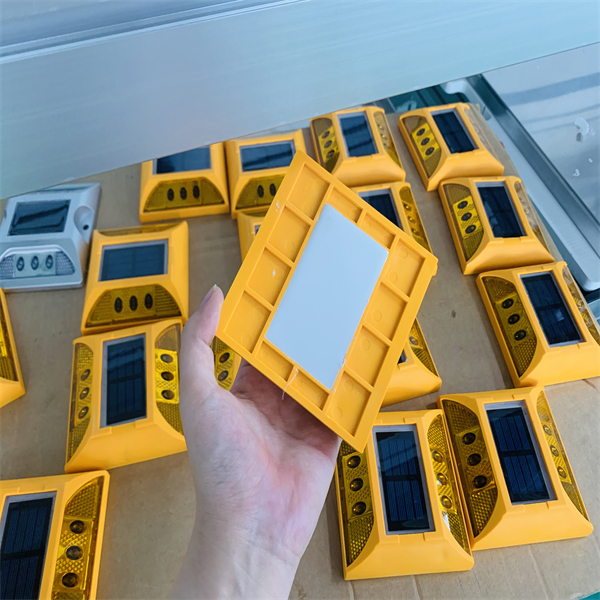

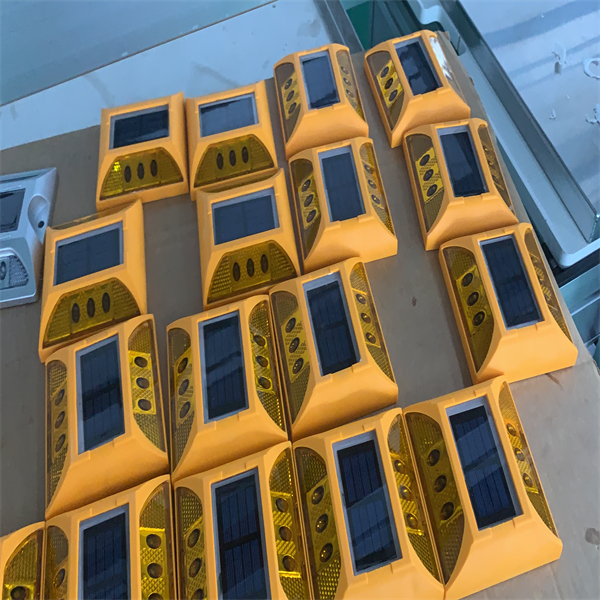

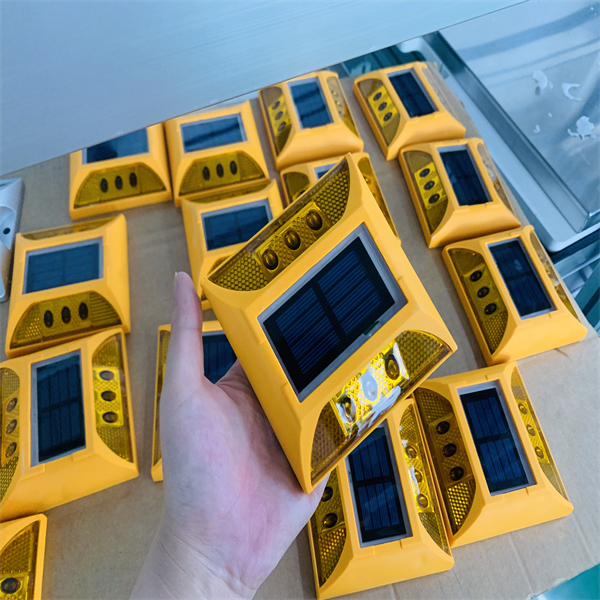

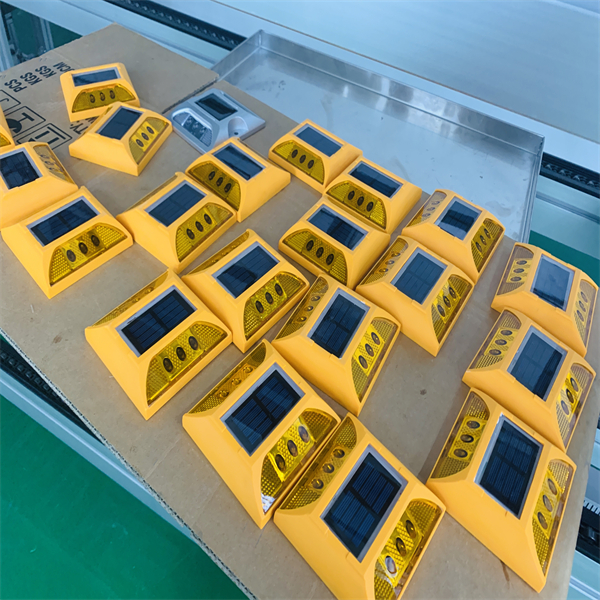

Hot Sale Solar Road Studs For Sale

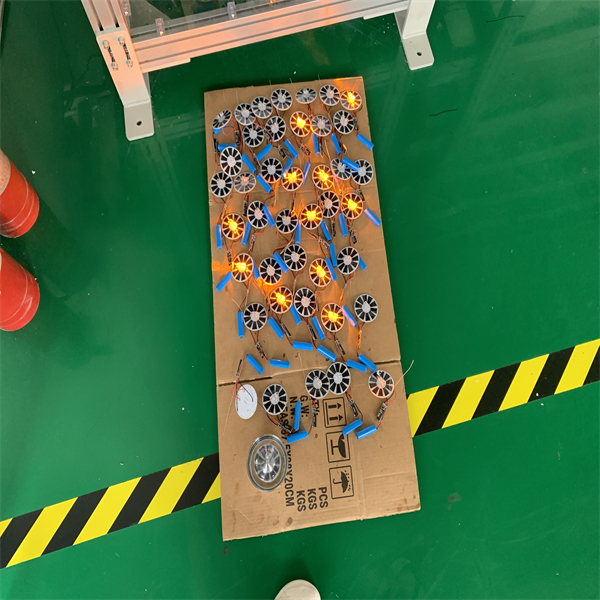

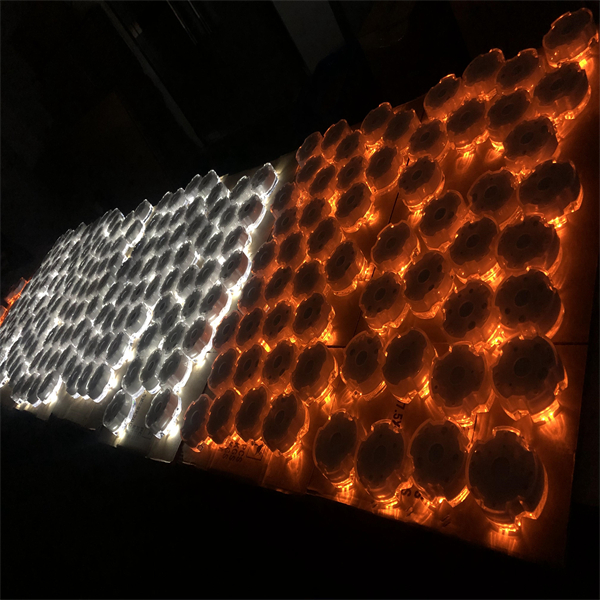

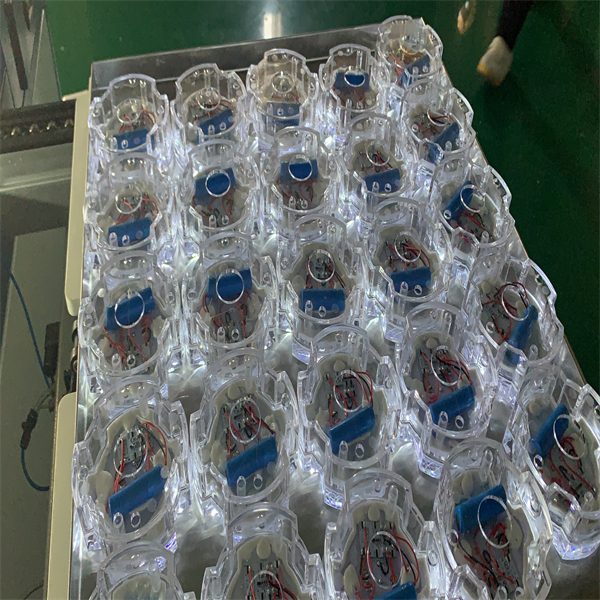

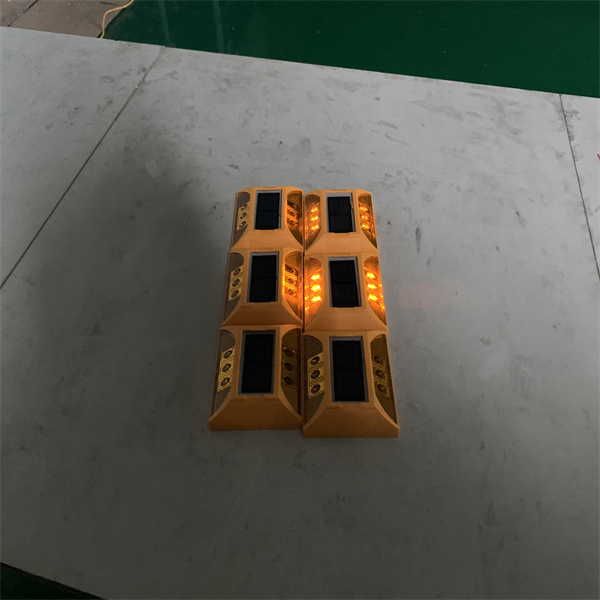

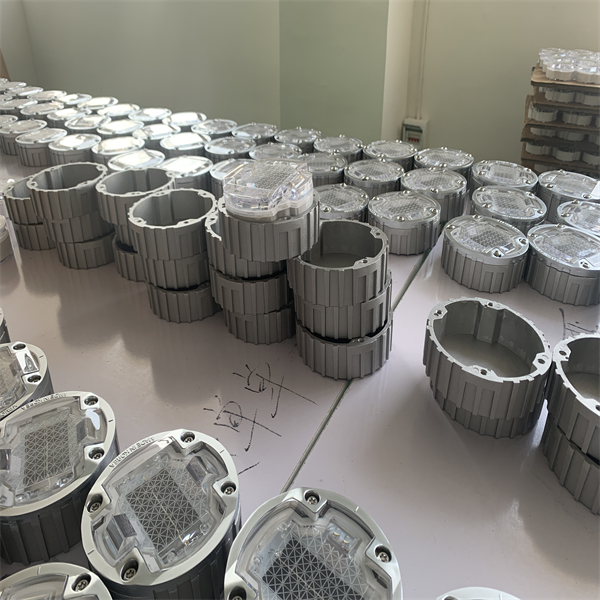

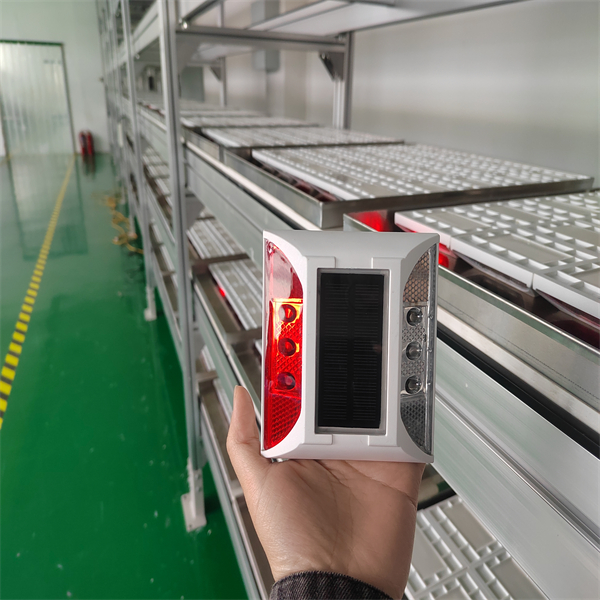

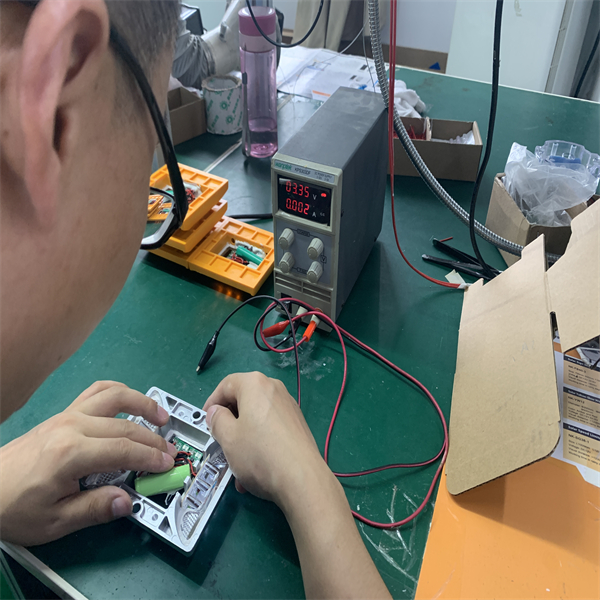

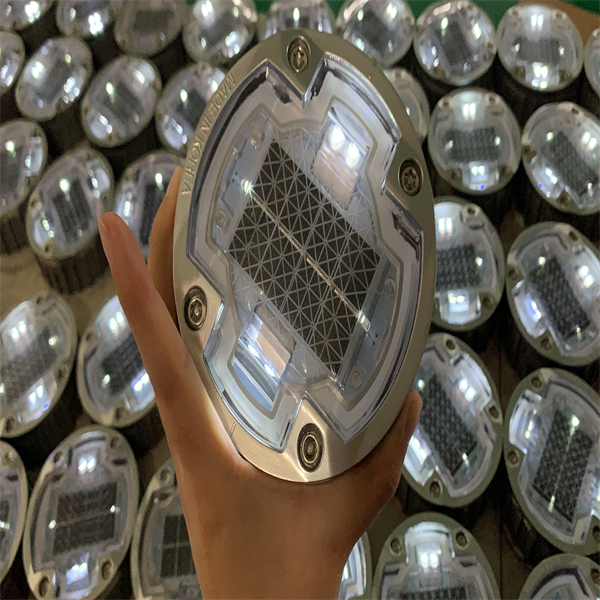

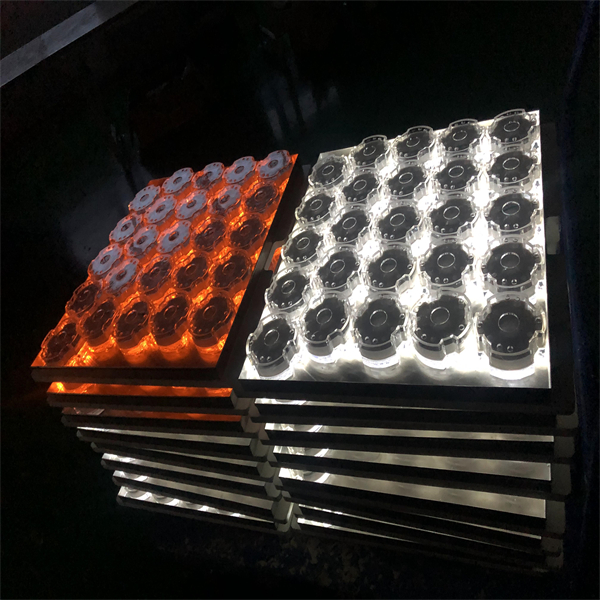

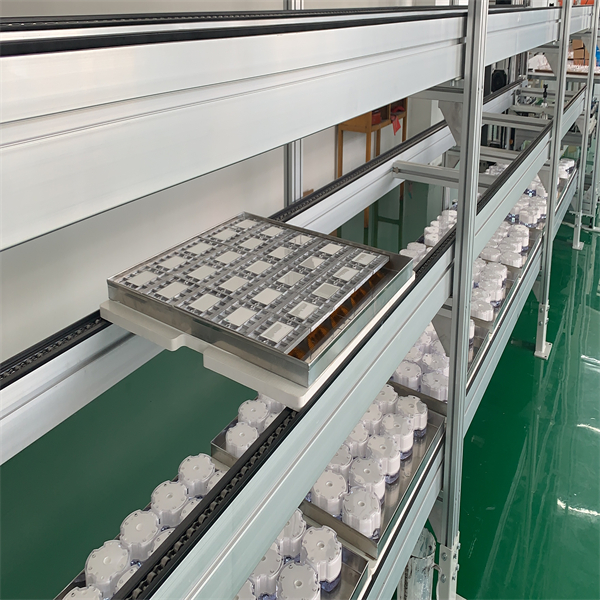

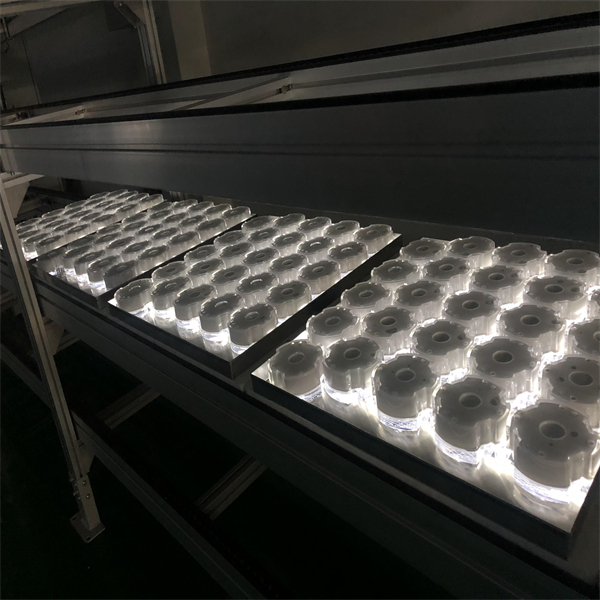

Electronic parts for Solar Road Studs must also be carefully chosen because issues with just one of them could lead to the failure of the entire system. Because Solar Road Studs must survive daily crushing and impact from moving cars, the welding must be dependable.

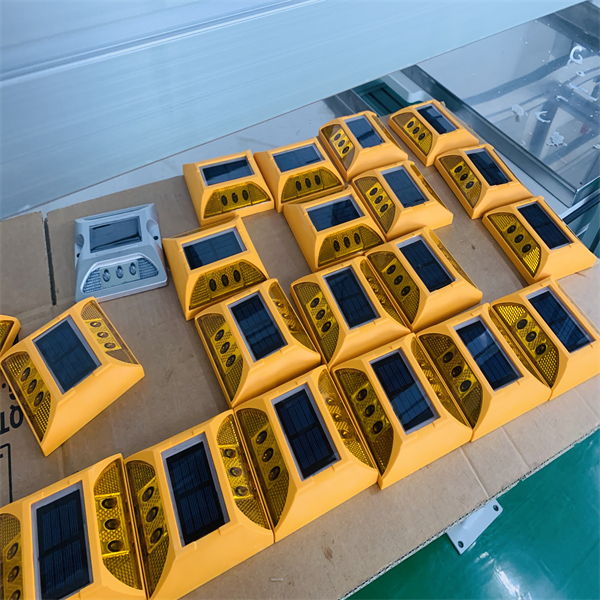

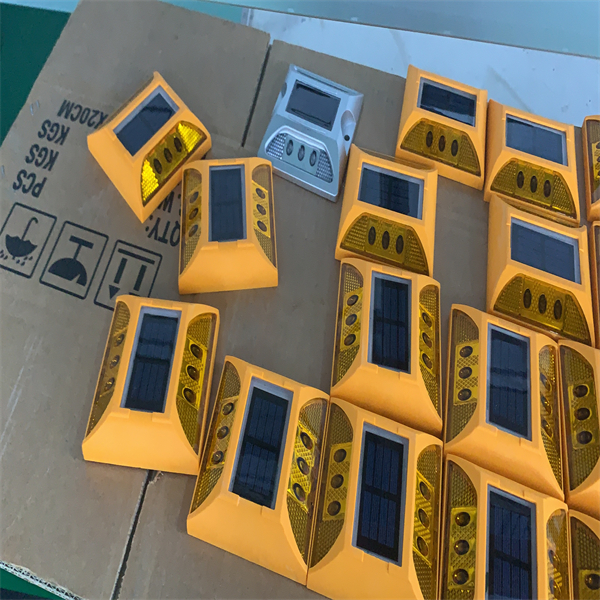

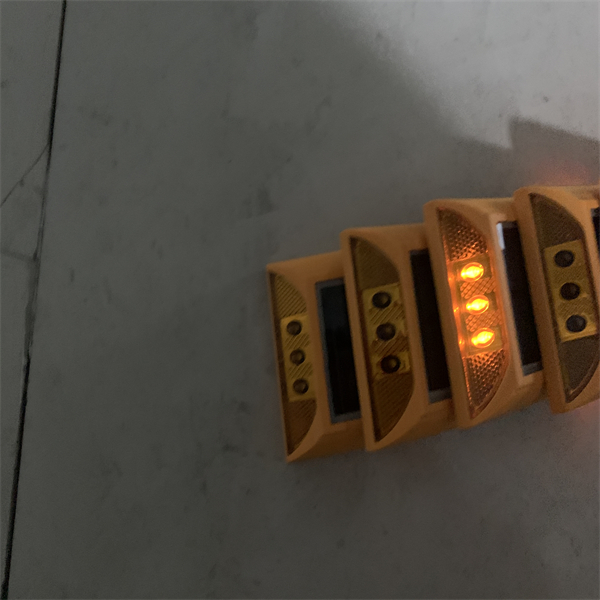

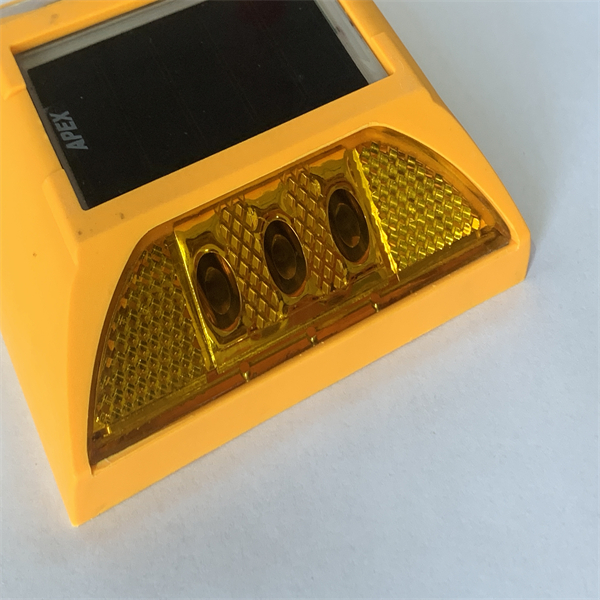

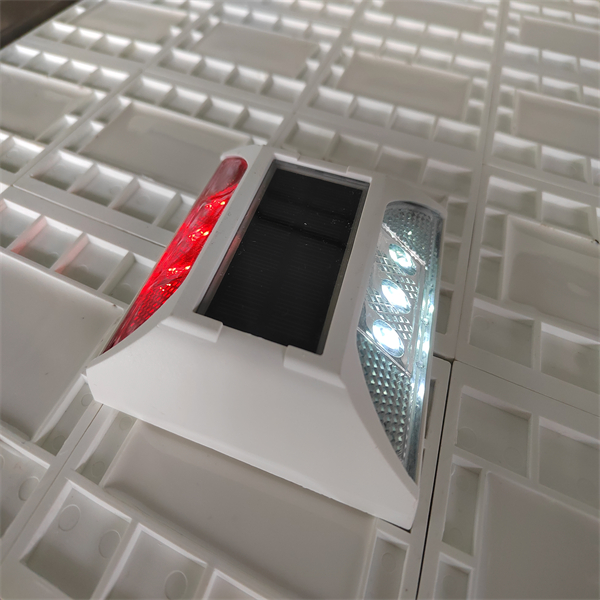

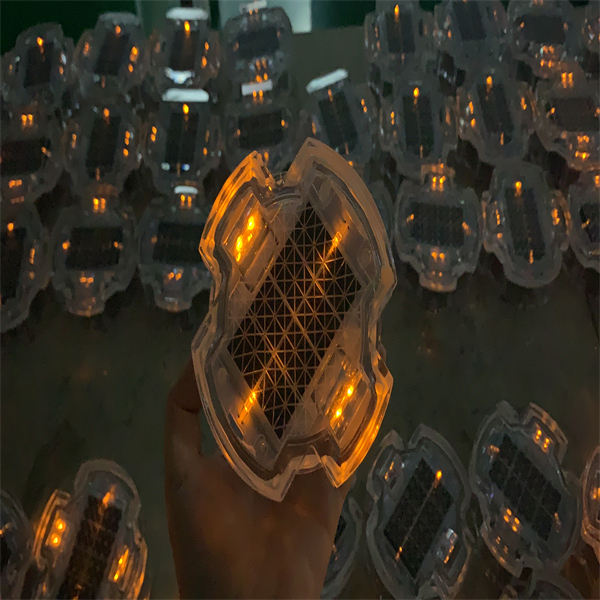

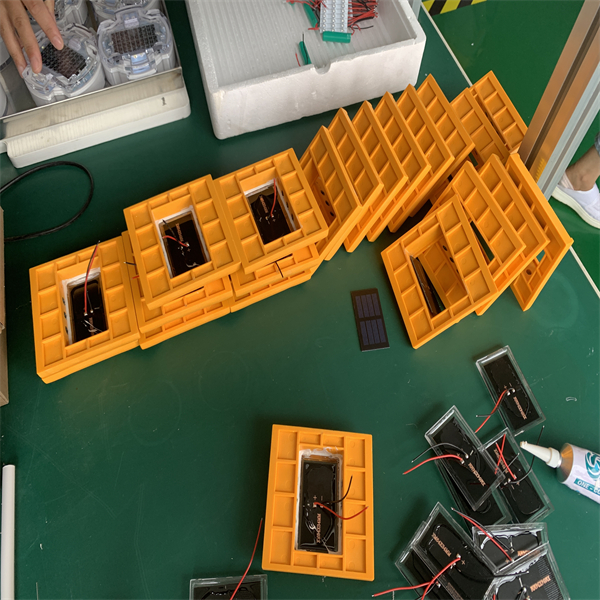

Electronic parts for Solar Road Studs must also be carefully chosen because issues with just one of them could lead to the failure of the entire system. Because Solar Road Studs must survive daily crushing and impact from moving cars, the welding must be dependable. The lines will get slack and fall off if the welding joints become slightly less secure. Because of this, you must choose high-quality Solar Road Studs items when selecting a welding gun and solder to guarantee that the solder joints are sturdy and dependable and can function for a long time in rather “harsh” conditions. Solar energy is directly absorbed by Solar Road Studs solar panels, which then transform light energy into electrical energy.

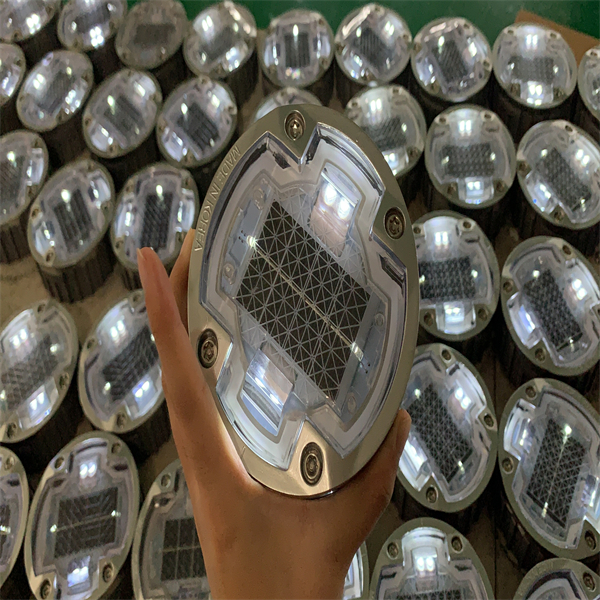

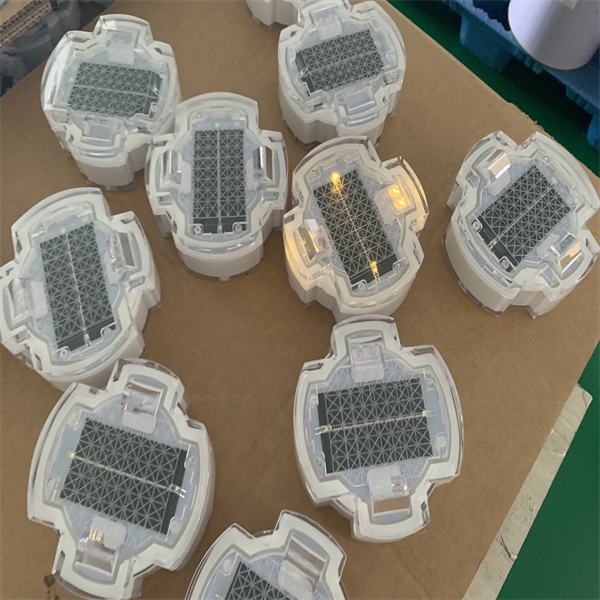

It might be considered the first link in the overall system that powers Solar Road Studs; the effectiveness of its operation directly affects the effectiveness of Solar Road Studs. Solar panels made of monocrystalline silicon are widely used right now. This is due to the fact that monocrystalline silicon solar panels have a relatively high photoelectric conversion rate of about 14%, which may maximize the conversion of solar energy into electrical energy and assure the functionality of Solar Road Studs. power supply. Additionally, high-hardness, wear-resistant circuit boards are required for solar panels. The pressure and abrasion of wheels are constantly felt by Solar Road Studs solar panels. If the strength is insufficient, it will be readily grounded and damage the solar panel’s conversion effectiveness.