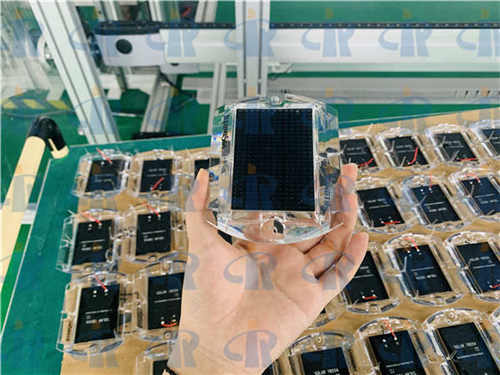

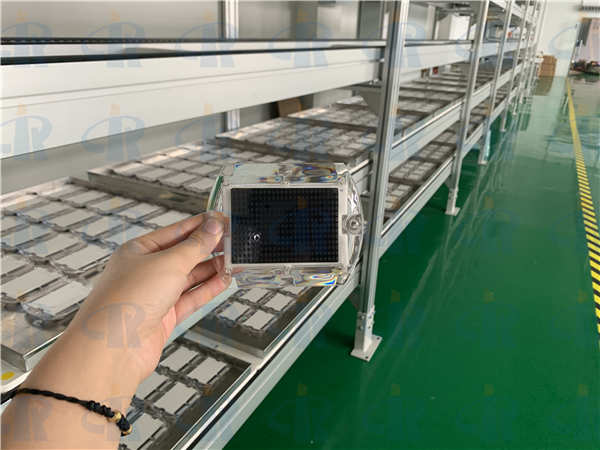

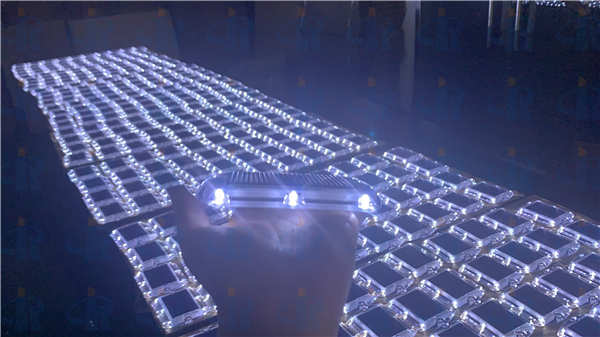

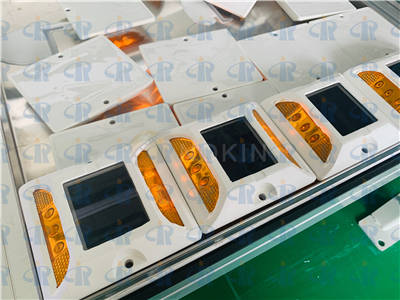

Liquid Control Expert produces solar road studs very fast

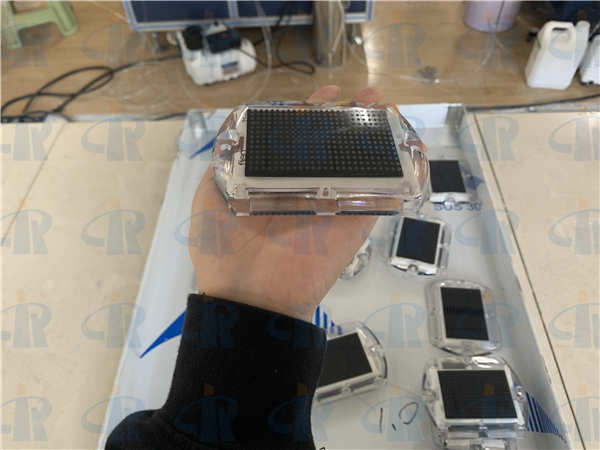

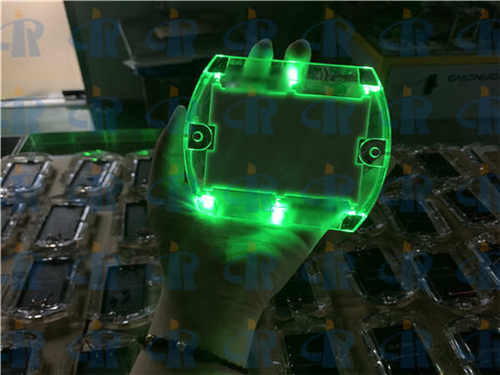

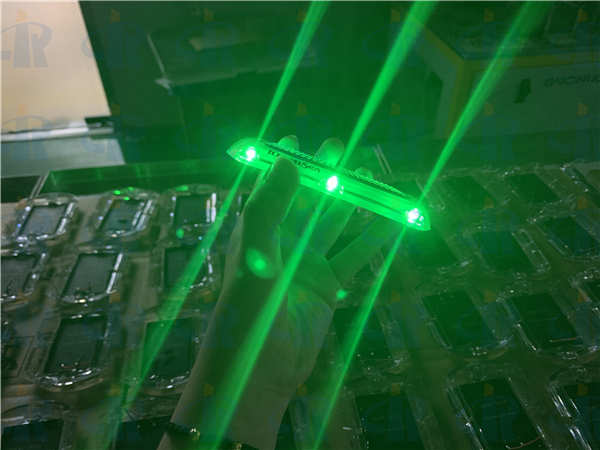

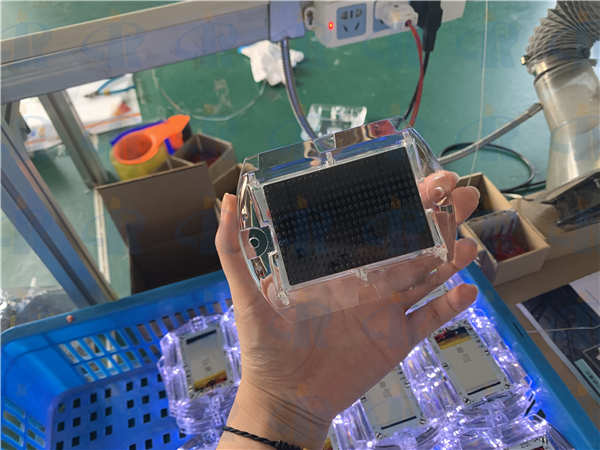

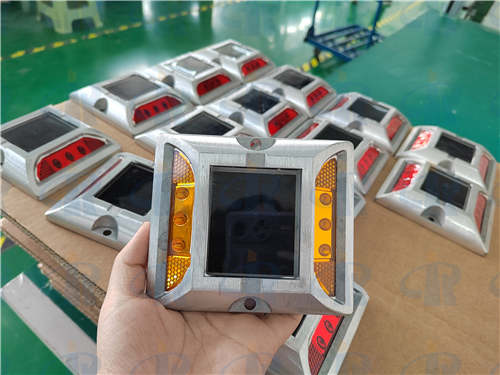

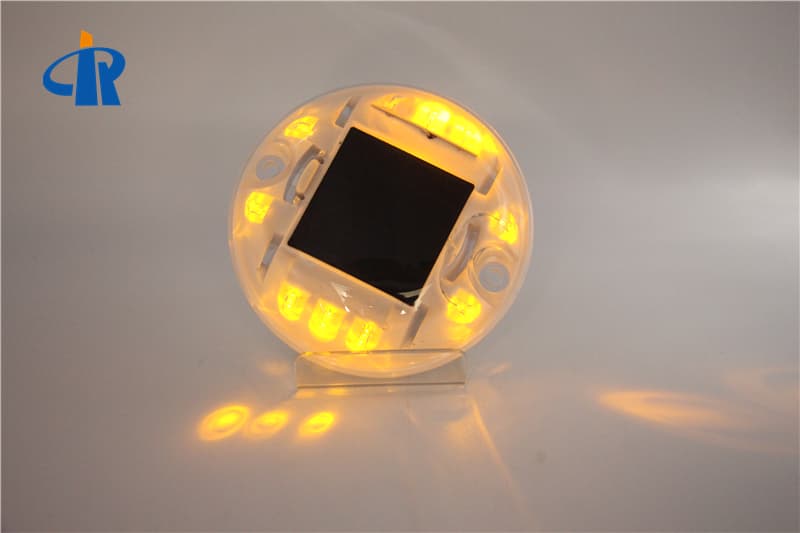

Generally, road stud products are used more often, but occasionally in other industries. Different types of road stud products can be regarded as cavities to be filled with different shapes, which can be adapted to various types of road stud product filling scenarios through programming.

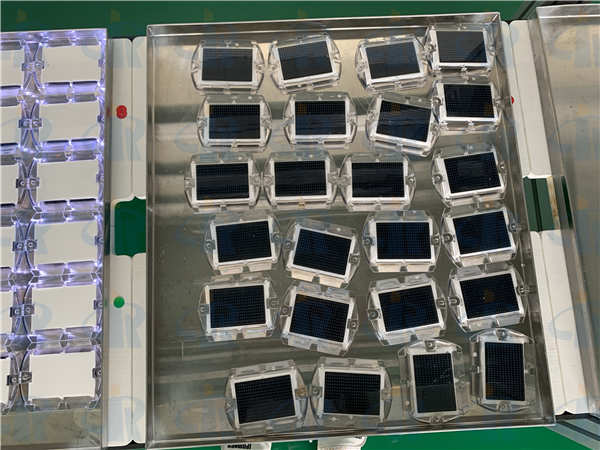

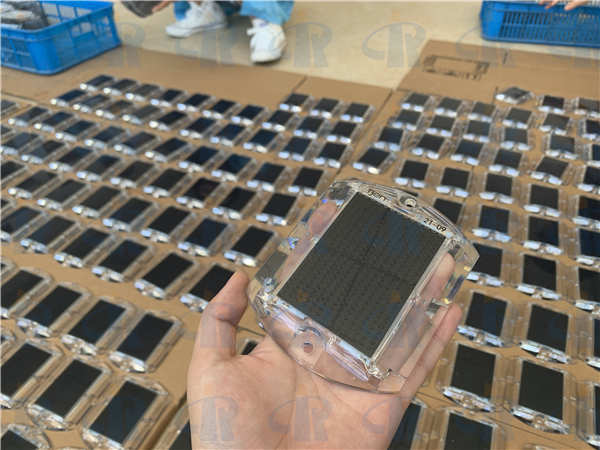

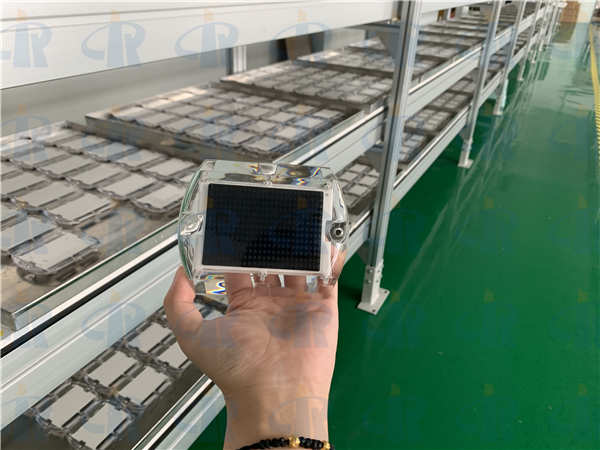

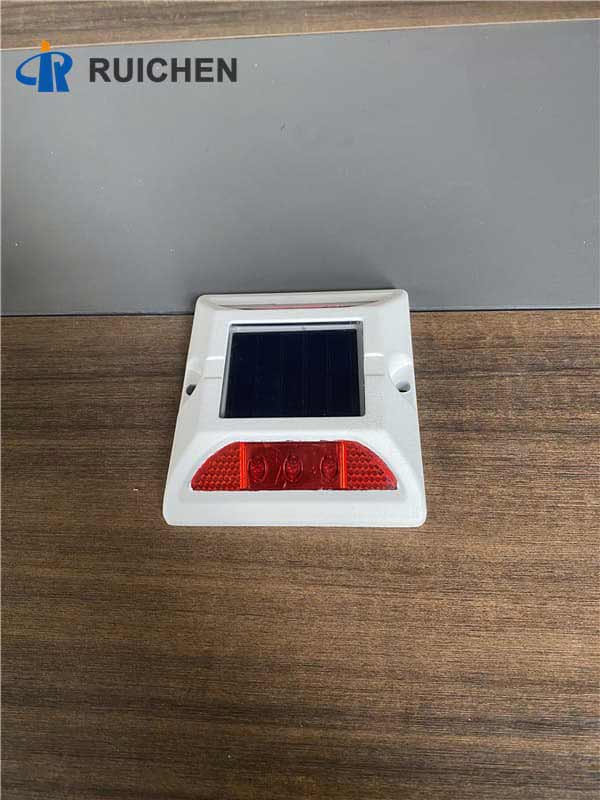

First of all, choose a solar road stud glue filling machine, which means that there is already a large production scale of solar road studs. Different road stud manufacturers have different production volumes and labor costs. Choosing road stud glue filling machine for glue filling process is also a big reason for the consideration of cost reduction.

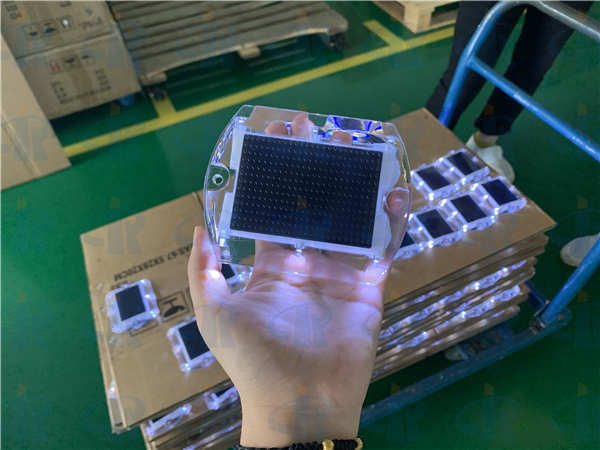

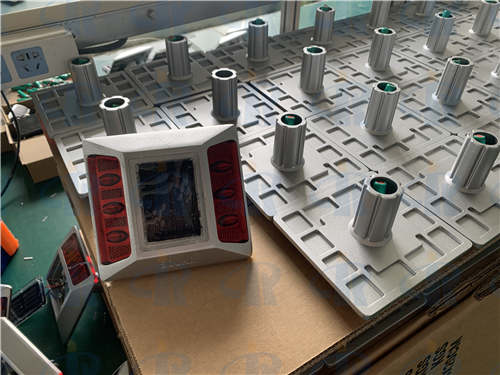

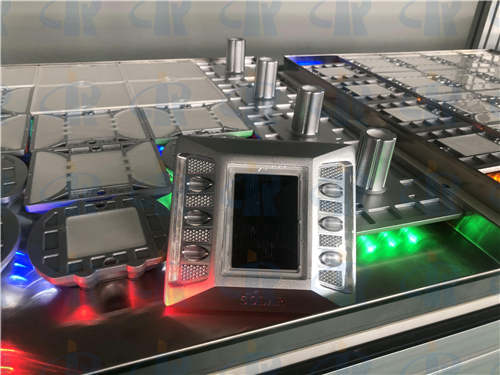

Ruichen Group can choose different types of solar studs potting machines. Semi-auto solar studs glue pouring machine or fully automatic road stud glue pouring machine? If there are many types of reflective studs, or if you only make a certain reflective studs product two to three days a week, you can choose a semi-automatic solar studs potting machine. If the output of road stud reflectors is very large, even three to four people a day can fill the glue manually. It would be a better choice to choose a fully automatic solar studs glue filling machine to improve efficiency.

Fully automatic solar road stud glue pouring machine using two-component AB glue such as epoxy resin, PU polyurethane and silicone. It can realize the functions of AB glue automatic proportioning, automatic glue mixing, automatic glue potting and so on. Generally, road stud products are used more often, but occasionally in other industries. Different types of road stud products can be regarded as cavities to be filled with different shapes, which can be adapted to various types of road stud product filling scenarios through programming.