Related performance requirements for Solar Road Studs

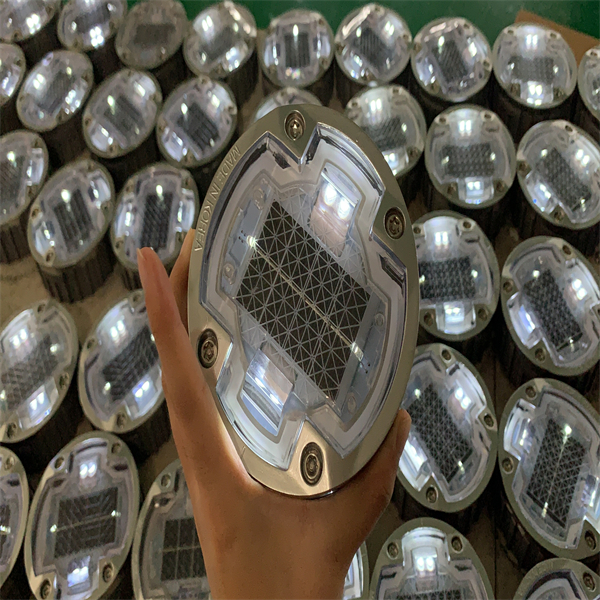

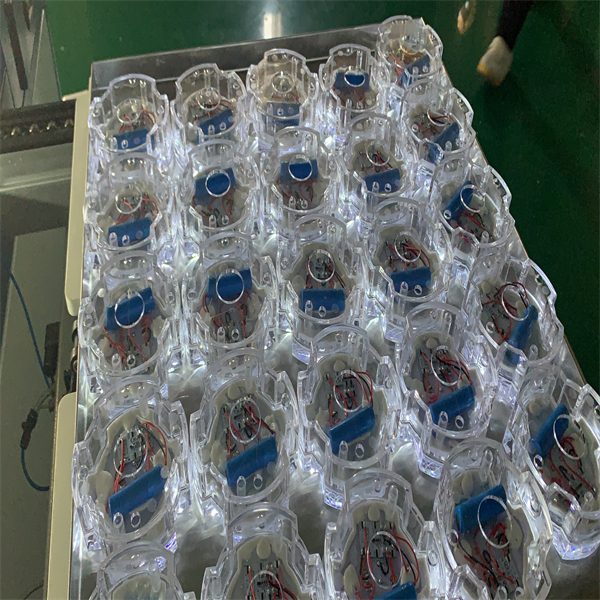

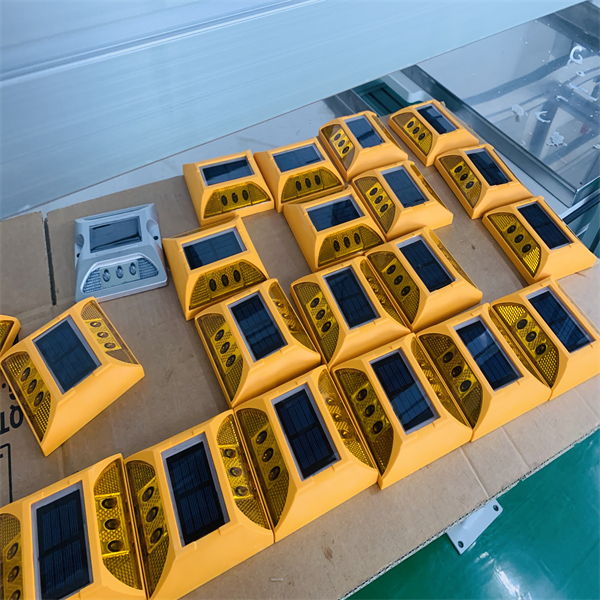

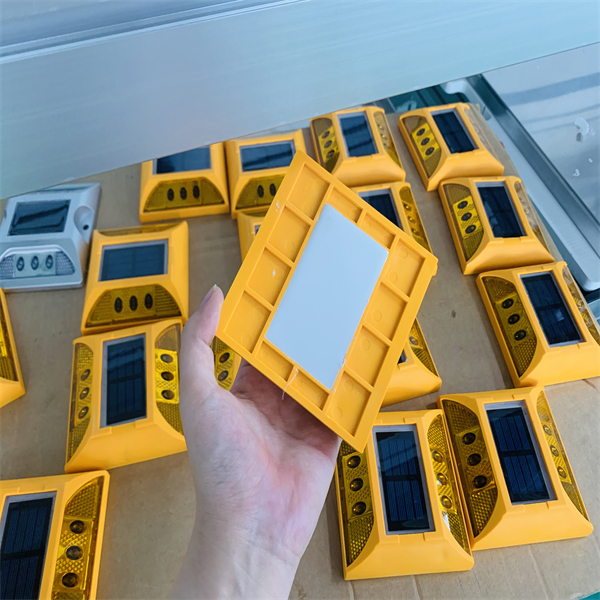

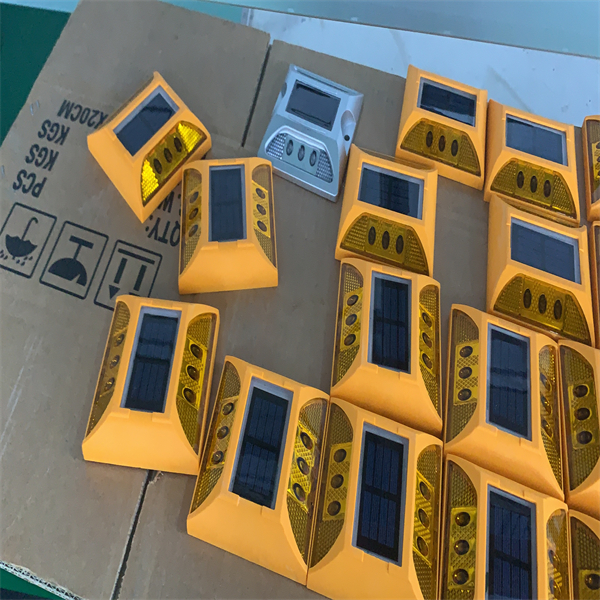

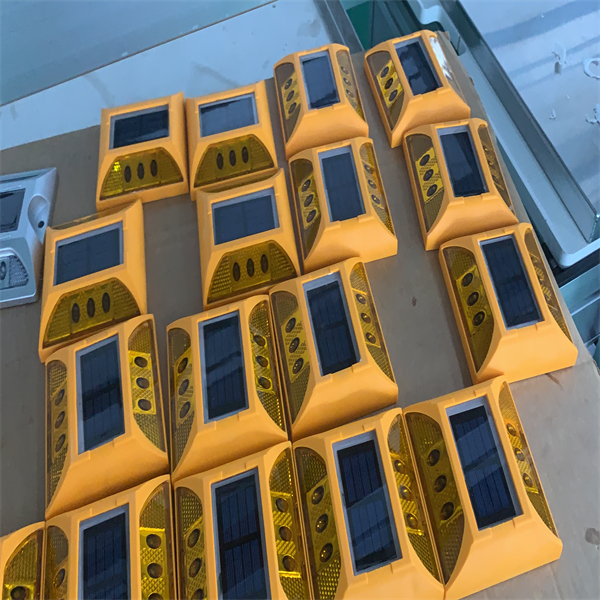

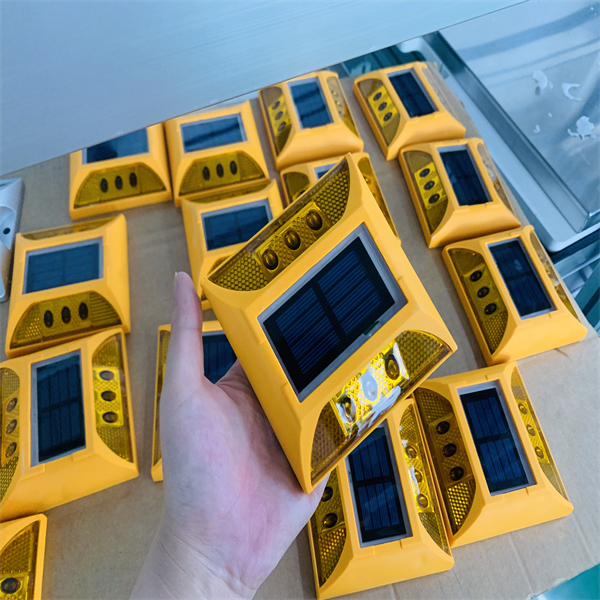

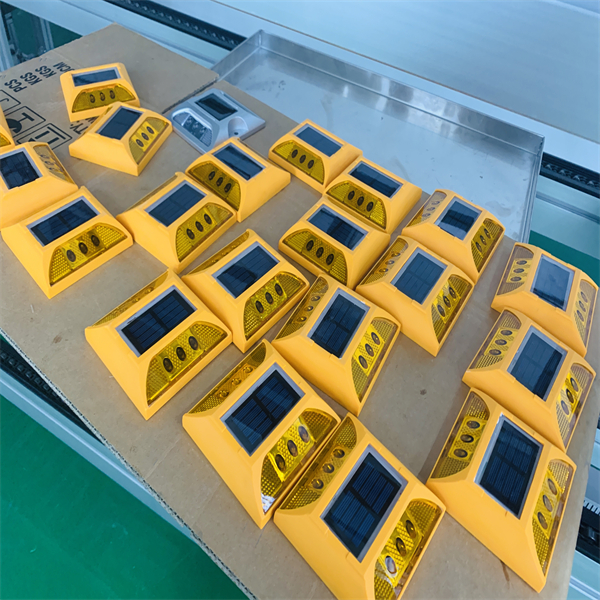

According to the requirements of the relevant technical standards of the Ministry of Transport, the compression index of Solar Road Studs must reach more than 10 tons. Compression resistance is the most basic condition for Solar Road Studs to work properly. The Solar Road Studs surface shell produced by Henan Ruichen Traffic Equipment Co, Ltd. is made of high-compression PC bulletproof material to enhance the compression resistance of its electronic components; some reinforcing ribs are designed on the shell to share the electronic components.

Compression performance requirements for Solar Road Studs:

According to the requirements of the relevant technical standards of the Ministry of Transport, the compression index of Solar Road Studs must reach more than 10 tons. Compression resistance is the most basic condition for Solar Road Studs to work properly. The Solar Road Studs surface shell produced by Henan Ruichen Traffic Equipment Co, Ltd. is made of high-compression PC bulletproof material to enhance the compression resistance of its electronic components; some reinforcing ribs are designed on the shell to share the electronic components. the pressure suffered.

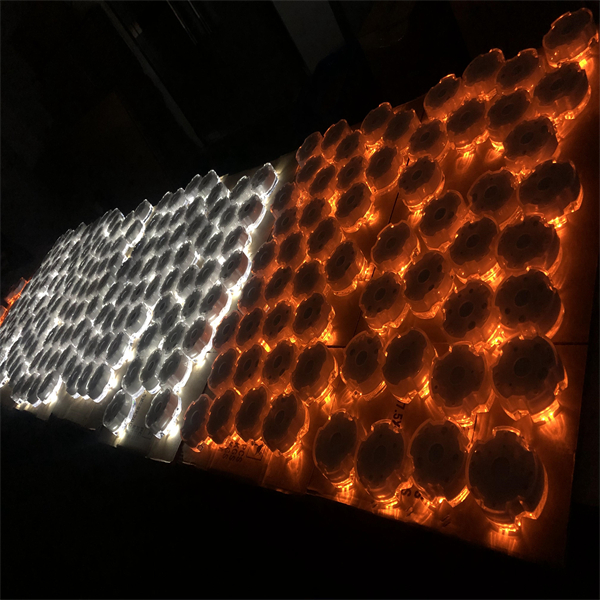

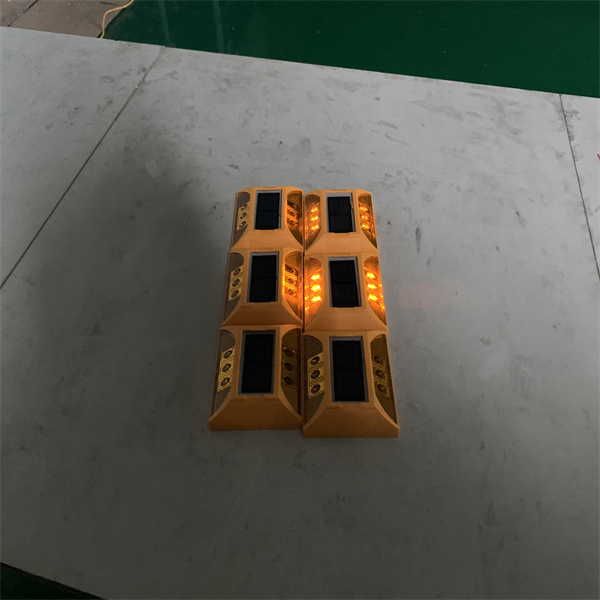

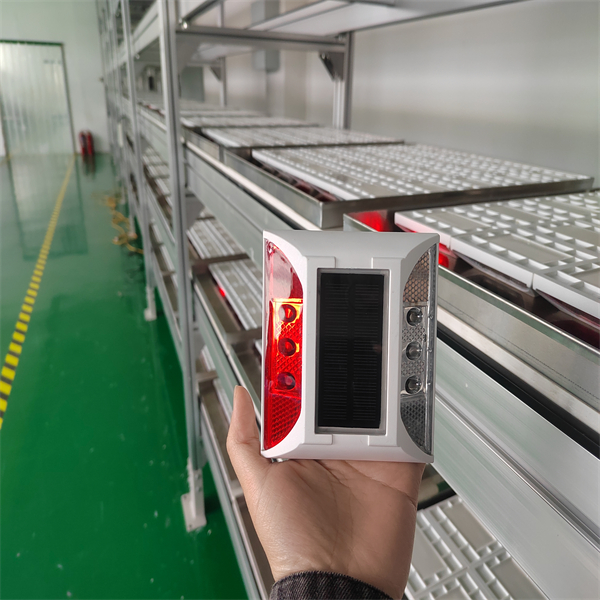

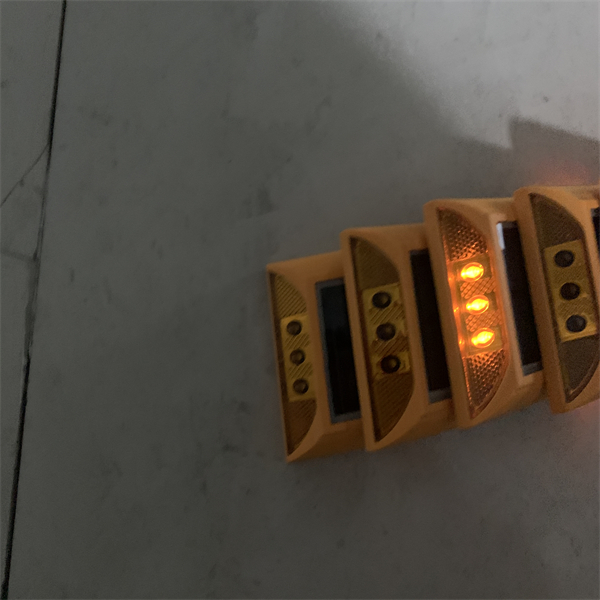

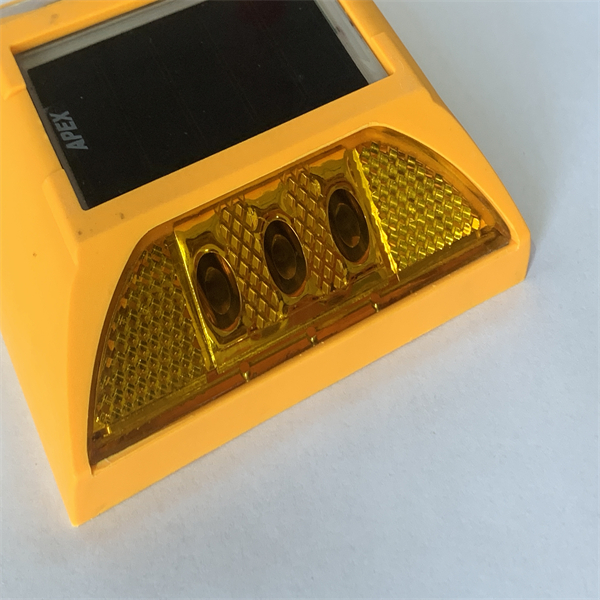

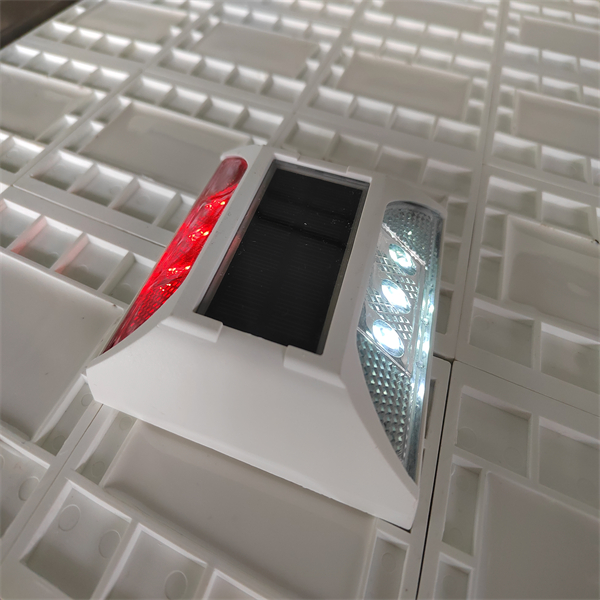

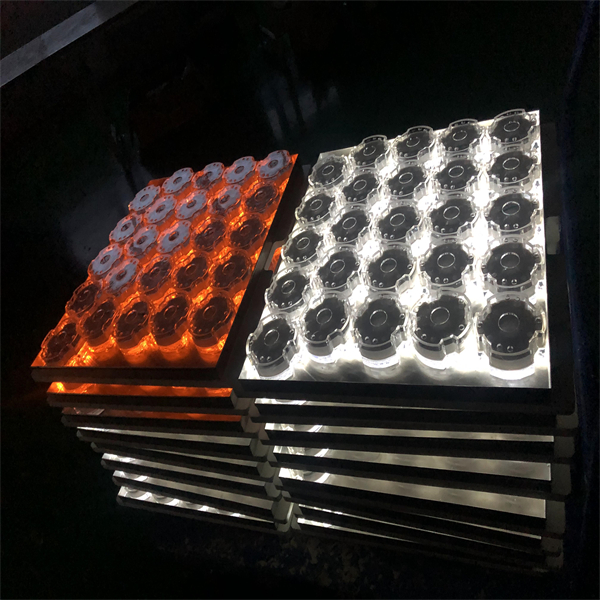

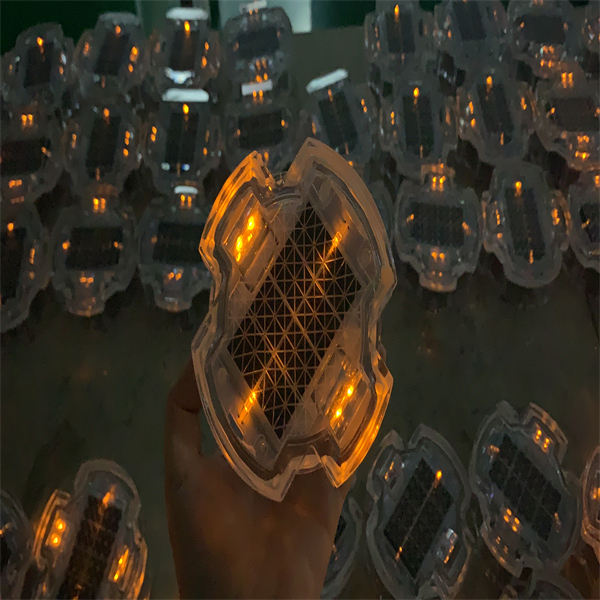

Brightness requirements for Solar Road Studs too:

The requirements of the relevant standards of the Ministry of Transport are 2000MCD. The brightness of Solar Road Studs produced by Fujian United Transportation reaches 5000MCD.

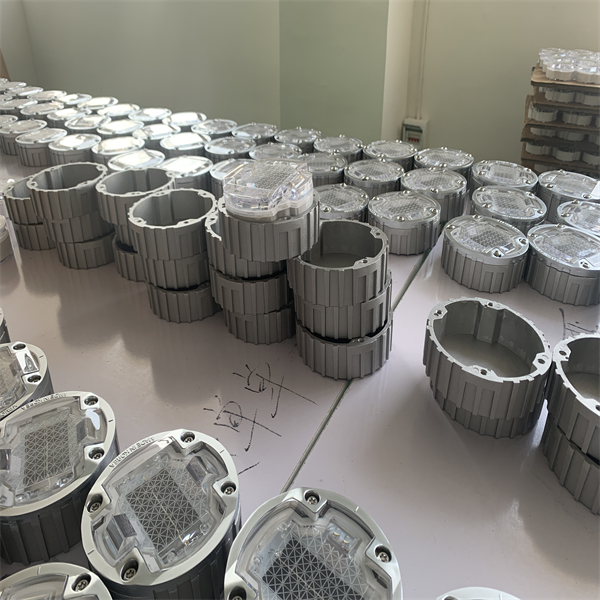

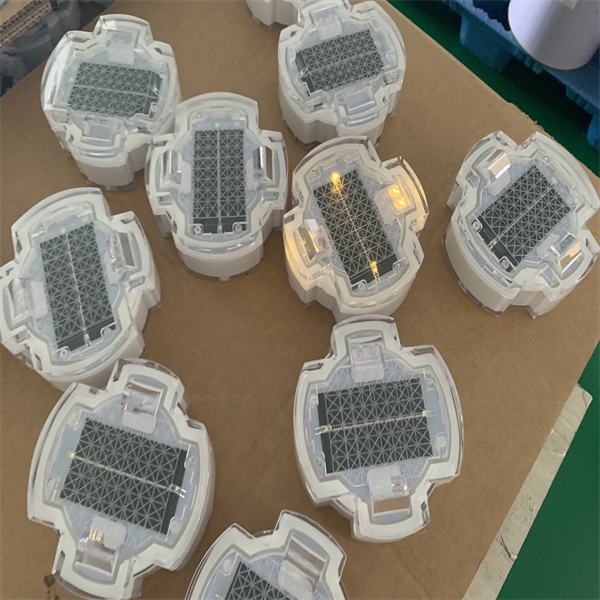

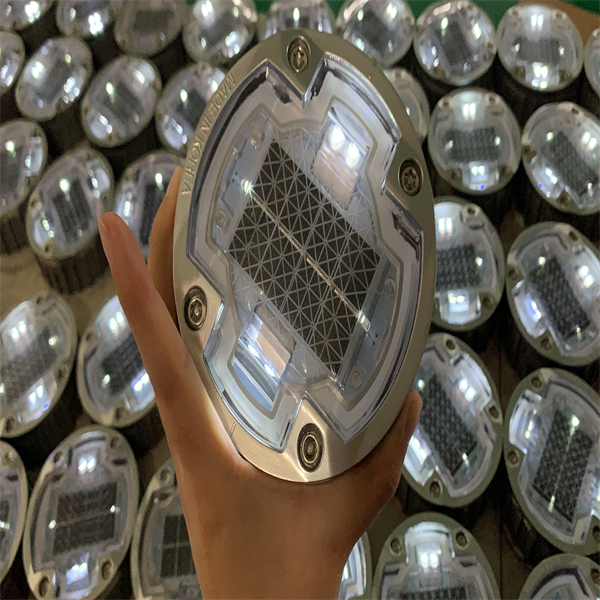

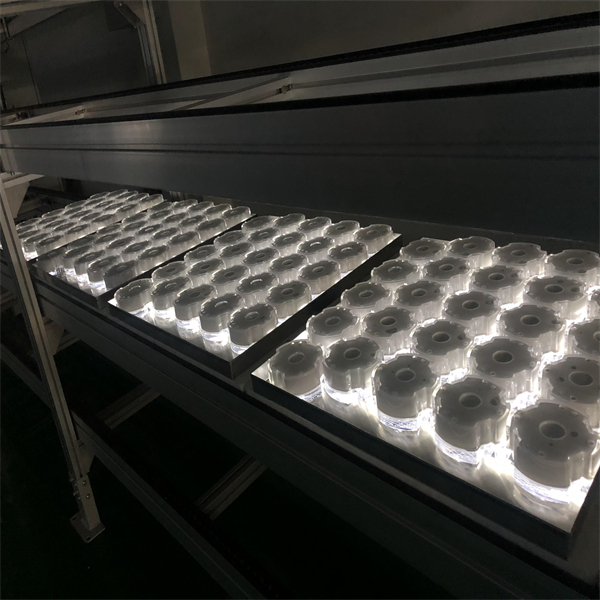

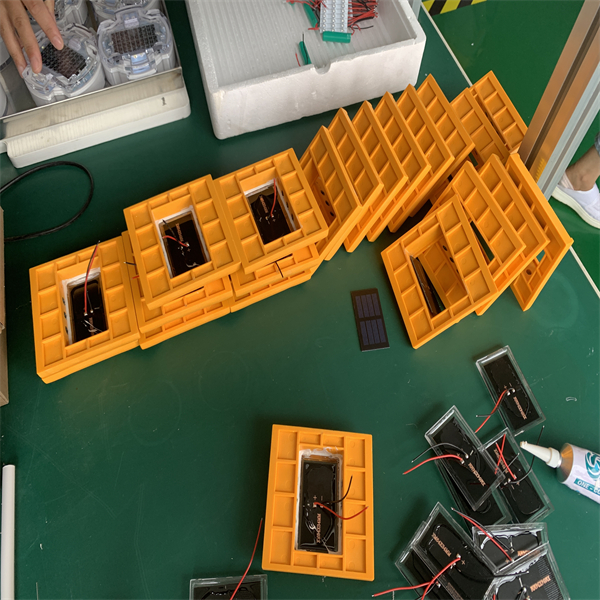

solar panel:

Solar panels directly absorb solar energy and convert light energy into electrical energy, which is the first link in the entire Solar Road Studs work system. The level of its work efficiency directly determines the quality of Solar Road Studs. The batteries used by Henan Ruichen Traffic Equipment Co, Ltd. are monocrystalline silicon panels. Monocrystalline silicon solar panels have a high photoelectric conversion rate of about 14%, which can convert solar energy into electrical energy to the greatest extent possible to ensure Solar Road Studs Energy supply at work.

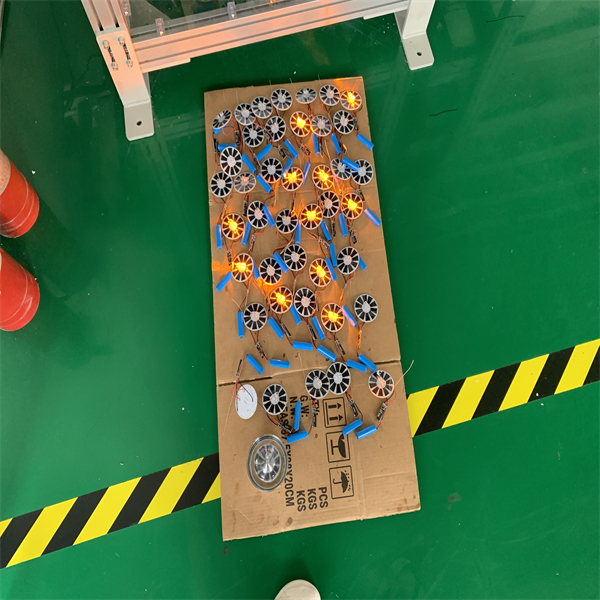

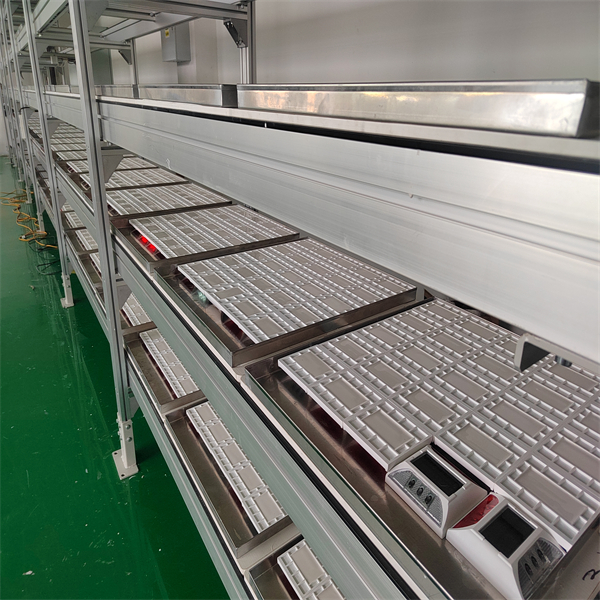

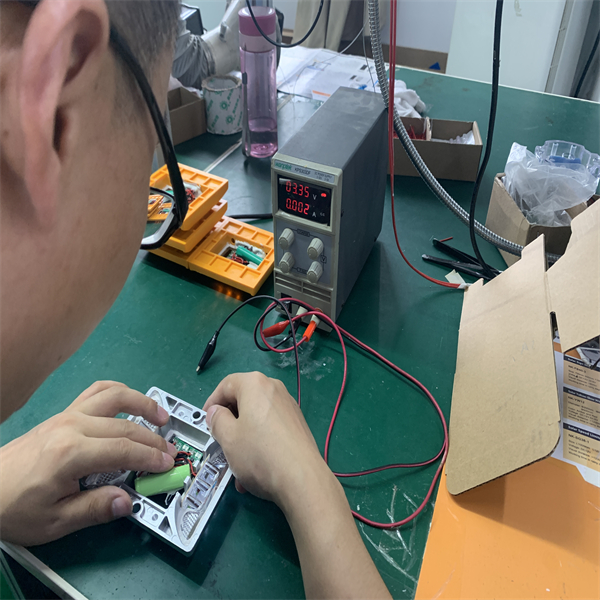

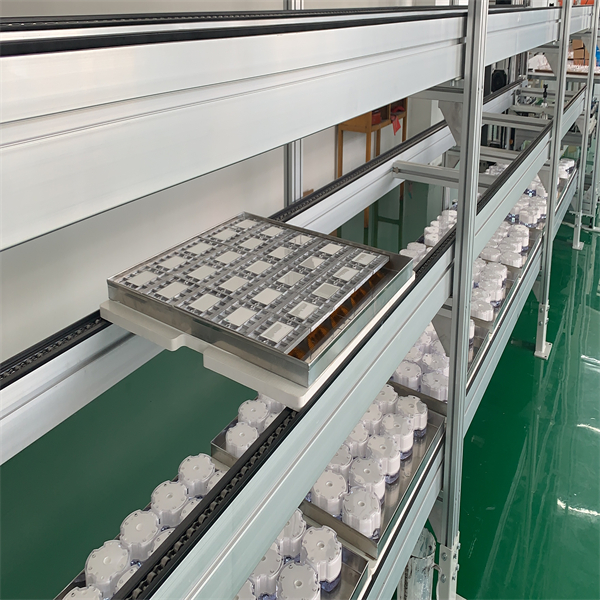

Battery matching performance:

Under standard test conditions, the Solar Road Studs are placed for 8 hours, and the rated capacity of the battery meets the needs of the Road Studs to emit light for 72 hours.