Relevant construction plan for Road Studs

According to the construction plan and the actual construction progress on the site, the required equipment will be transported to the Road Studs construction site by car as soon as possible, and sufficient testing equipment will be equipped. And do a good job in the application for the start of construction, and coordinate with the owner, the supervision engineer, other construction units, and the locality. In order to achieve the high-quality and efficient completion of this project, our company has selected a batch of relatively new, good-performance construction machinery and equipment suitable for the project for production and construction according to the characteristics and needs of the project, and its Carry out necessary debugging and maintenance to keep it in a good condition, and organize entry and exit in a planned way according to construction arrangements to reduce environmental pollution.

Project Overview:

The Road Studs of this tender section set the starting station number K8+400, the end station number K15+800, and the total length of the route is 7.4 kilometers. 1480 Road Studs are installed across the board.

Construction preparation:

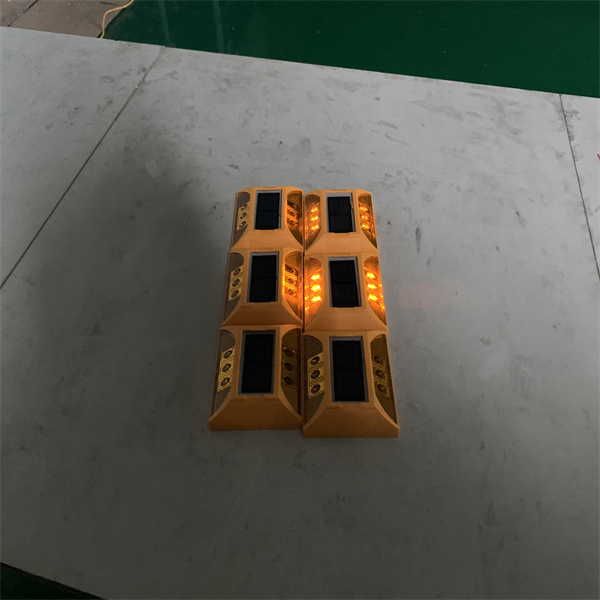

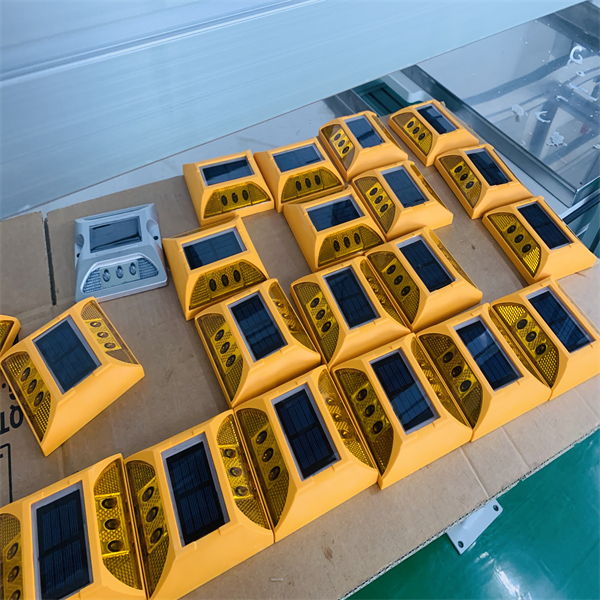

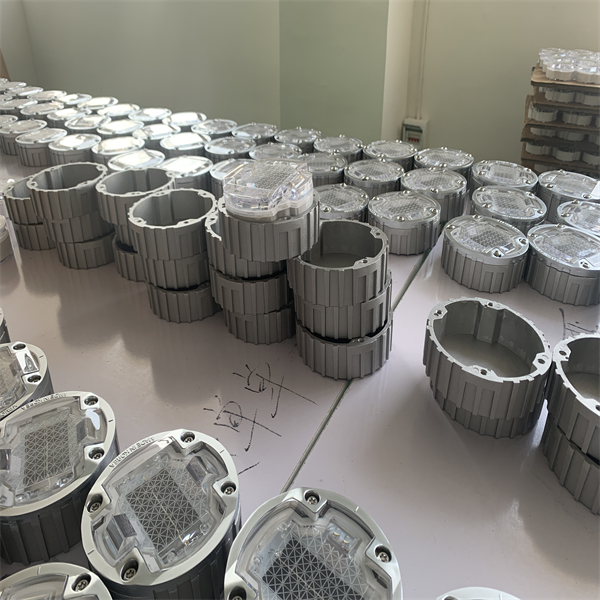

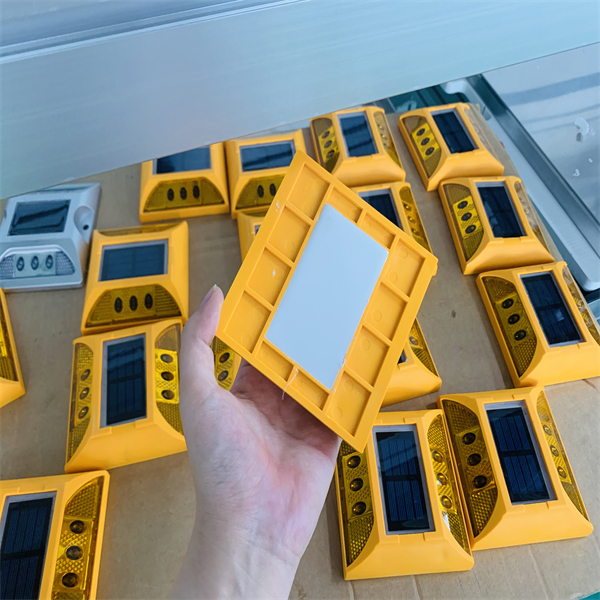

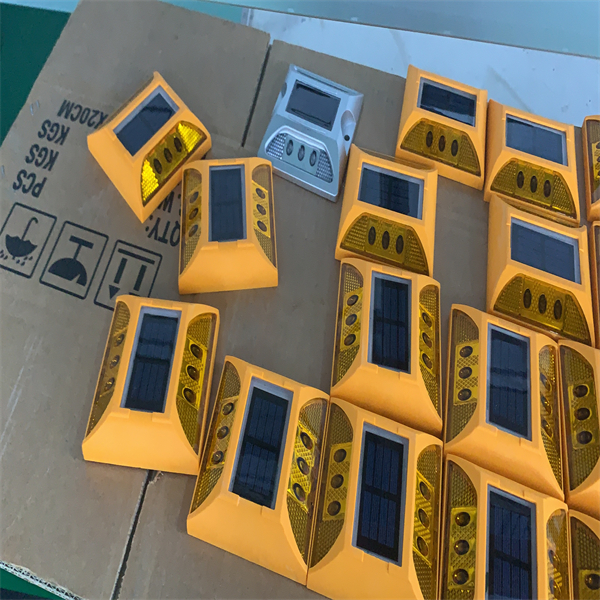

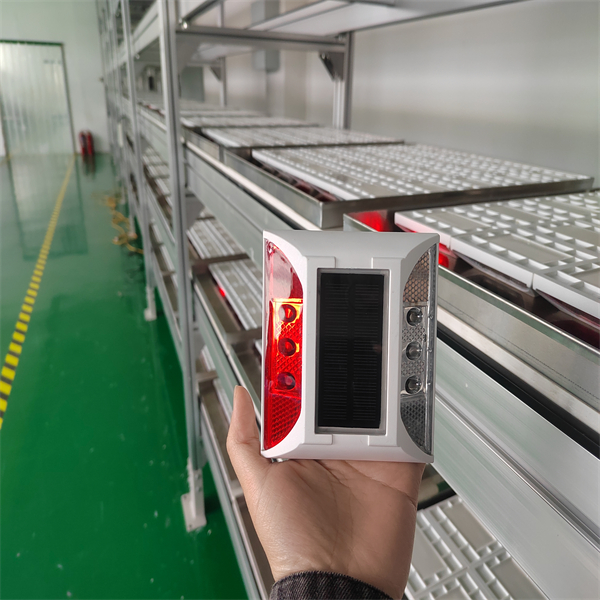

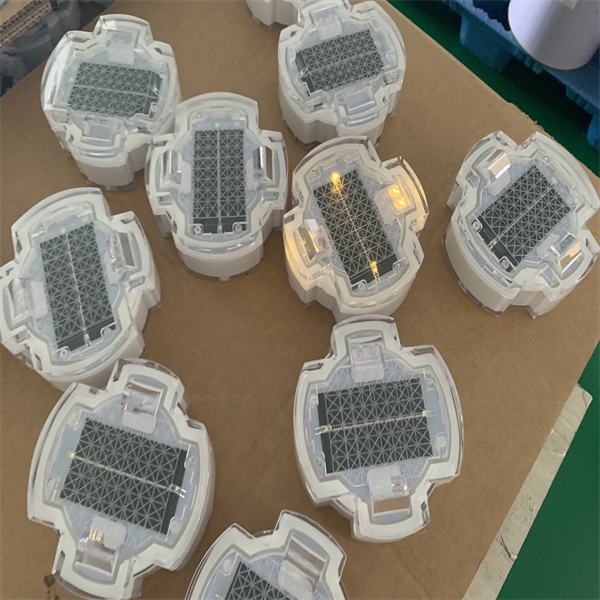

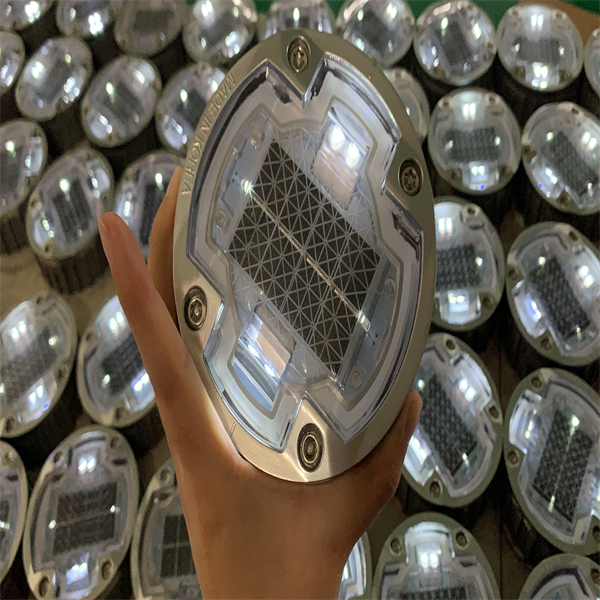

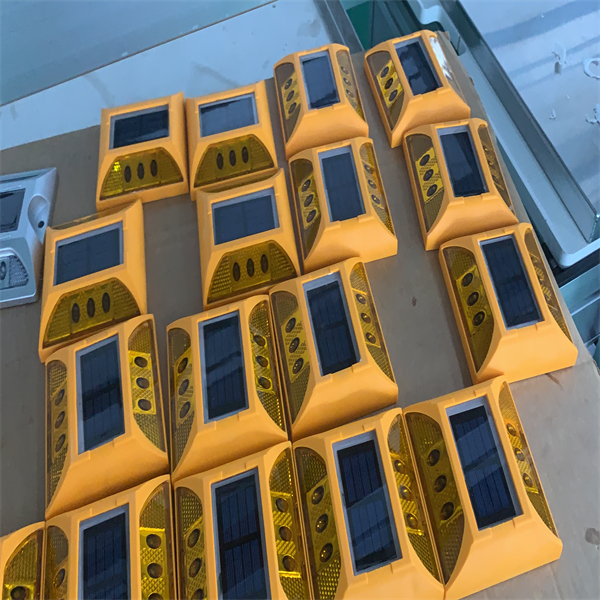

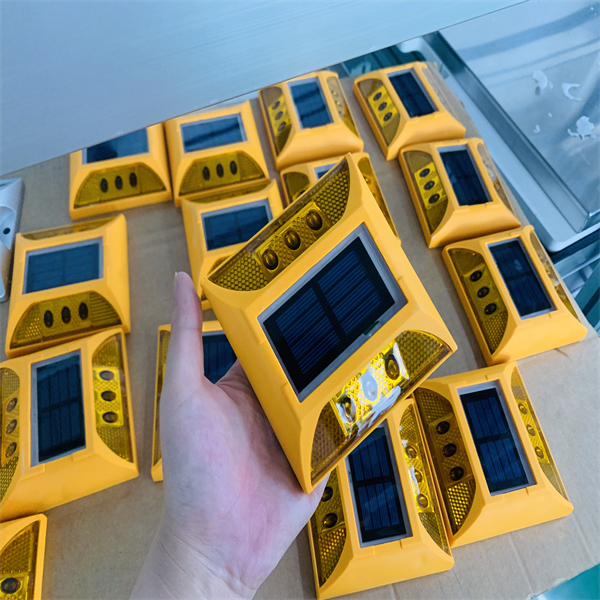

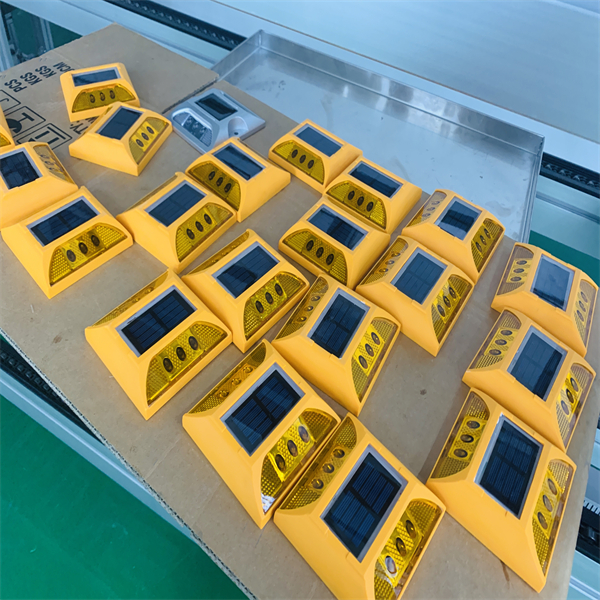

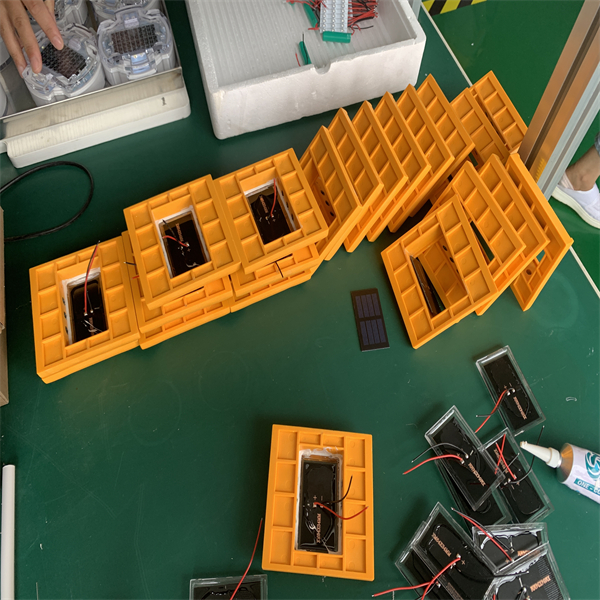

1, Road Studs construction material preparation

According to the requirements of the bidding documents of this project and relevant national regulations, construction design drawings, familiar with the regional building materials market, use a good business relationship and experienced inspection team to purchase materials, and ensure sufficient supply of materials, progress on schedule and excellent engineering quality.

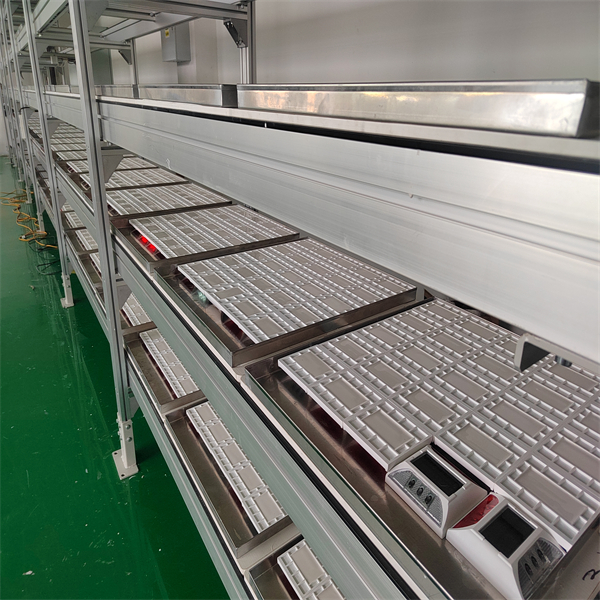

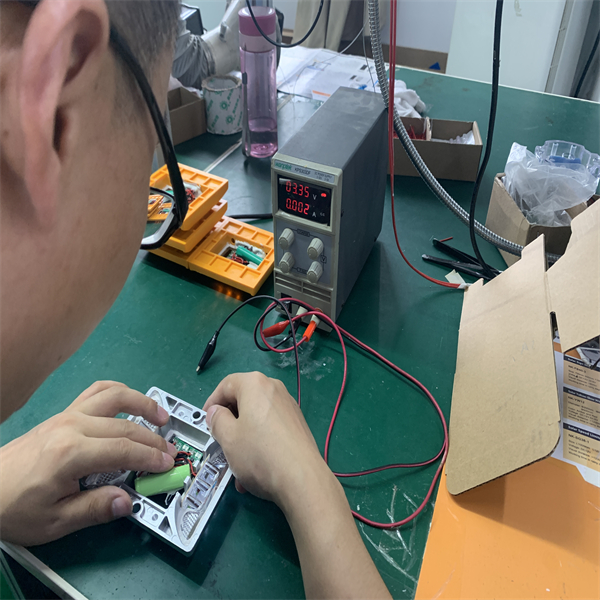

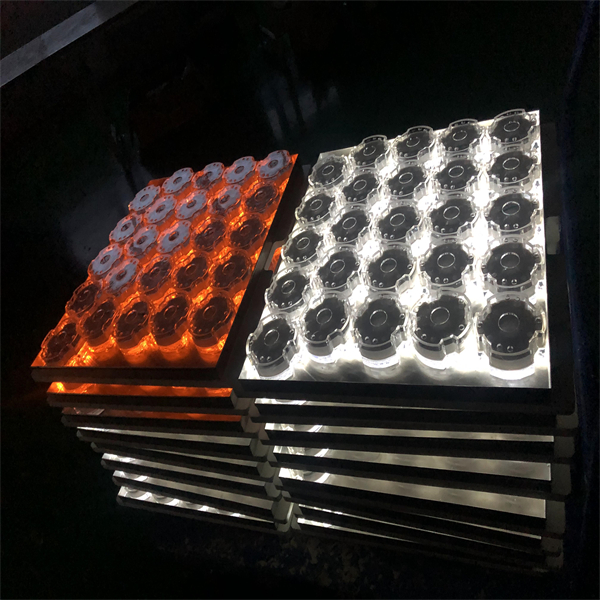

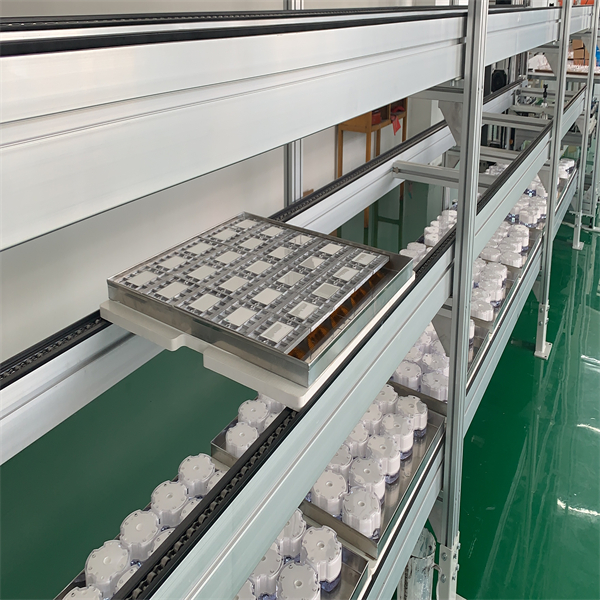

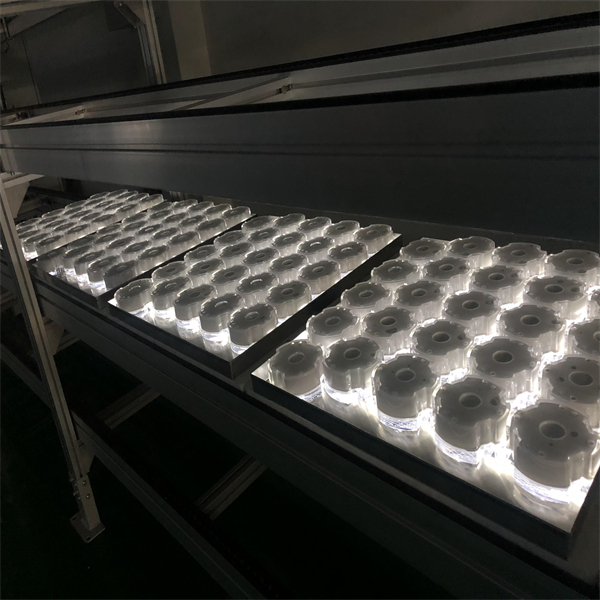

2, Road Studs construction equipment preparation

According to the construction plan and the actual construction progress on the site, the required equipment will be transported to the Road Studs construction site by car as soon as possible, and sufficient testing equipment will be equipped. And do a good job in the application for the start of construction, and coordinate with the owner, the supervision engineer, other construction units, and the locality. In order to achieve the high-quality and efficient completion of this project, our company has selected a batch of relatively new, good-performance construction machinery and equipment suitable for the project for production and construction according to the characteristics and needs of the project, and its Carry out necessary debugging and maintenance to keep it in a good condition, and organize entry and exit in a planned way according to construction arrangements to reduce environmental pollution.

3, Road Studs construction staff preparation

In order to ensure the construction quality of the project, Ruichen Traffic has set up a project manager department for this project. According to the work content of this sub-project, the labor force is organized according to professional teams, forming a number of basic professional teams: Road Studs construction team and comprehensive construction team. Each professional construction team is composed of 2-3 labor teams. Professional teams enter the site in sequence according to the requirements of streamlined operations.

Construction method:

Construction process of Road Studs:

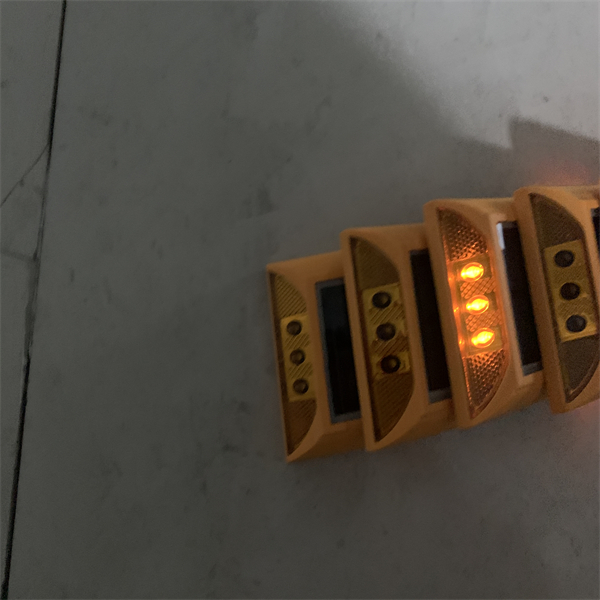

Clean the road surface → apply epoxy resin adhesive → release pressure protruding road signs → inspect the quality → finish.

1. The Road Studs shall be set up according to the drawings or the location indicated by the supervisor, and the road surface shall be dry and clean and free of debris. First, use road cones to seal off the construction site. The construction personnel wear reflective clothing and the road cones should be more than 50 meters away from the operators. There should be a safety officer on the construction site to direct traffic safety.

2. Use a ruler to determine the installation position, ensure that each position is in a straight line longitudinally, and aligned horizontally, left and right, and the installation distance shall be subject to the design requirements.

3. The road surface should be dry, and use a steel brush to brush the ground to remove the floating dust.

4. Use an electric hammer with a diameter of ∮16mm to drill the hole, the depth of the hole is 1cm greater than the height of the nail foot of the road sign.

After drilling the hole, blow the dust out.

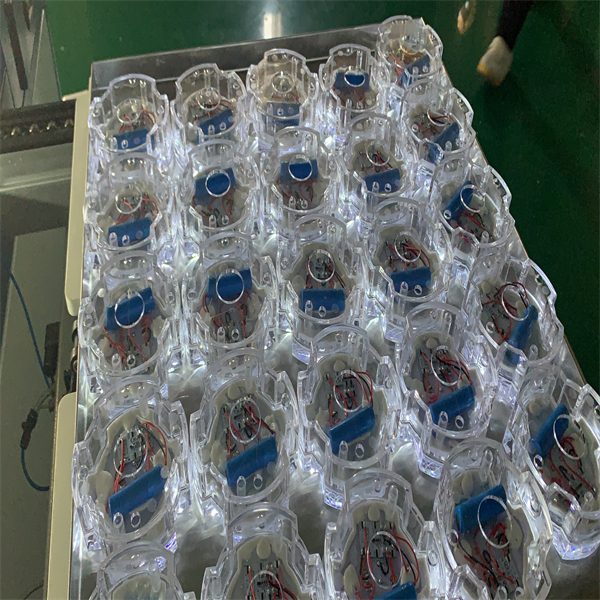

5. The ratio of glue is that epoxy resin is 1:1 to curing agent, and then 10%-30% cement is added as filler. Each mixing time is about three kilograms, and the gel should be mixed evenly and the color should be consistent.

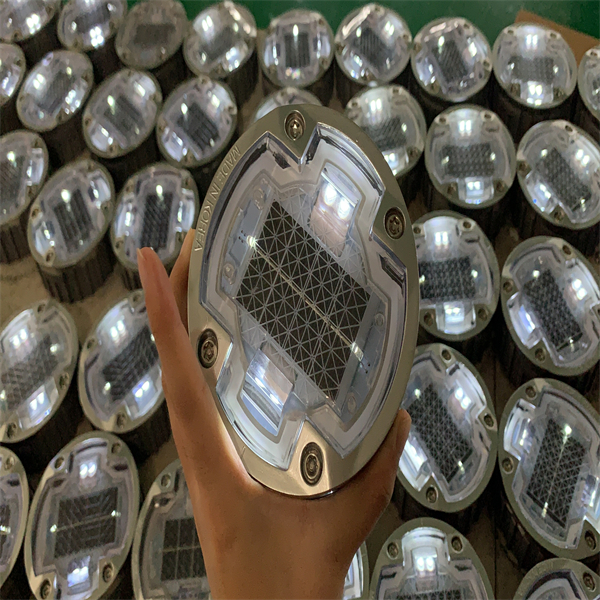

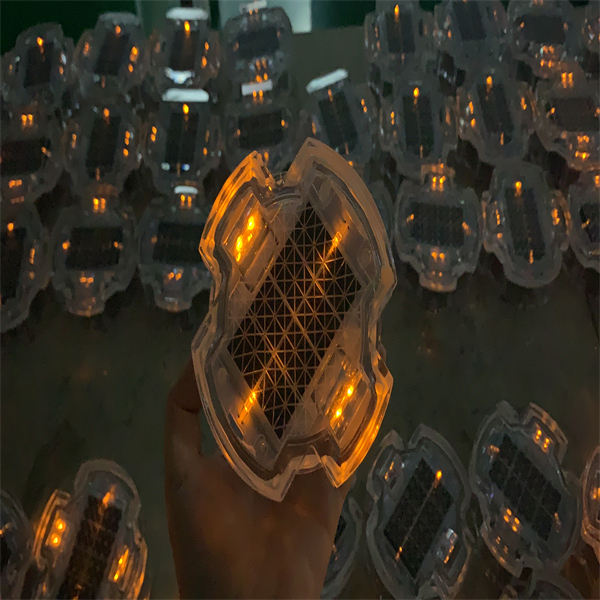

6. During the construction of Road Studs, personnel cannot hold the mirror with their hands, but can only hold both sides to avoid dirtying the reflector.

- When installing Road Studs, the road surface should be cleaned and the glue used should be moderate. It should not only stick to the bottom of the road sign, but also not overflow too much. If it overflows too much, it will easily dirty the reflector of Road Studs; if there is any front part of the reflector of Road Studs If the glue overflows, it should be scraped off carefully. After it is glued, turn it around twice so that the glue can stick to the ground and the spike body more evenly.

8. Clean up road debris after installing Road Studs.

9. The curing time of the glue is four hours, and the road section should be closed within four hours to ensure that vehicles cannot press Road Studs.

10. It is best to construct at night for the sections that have been opened to traffic.