What is the failure mode of Reflective Road Studs and the cause of the problem?

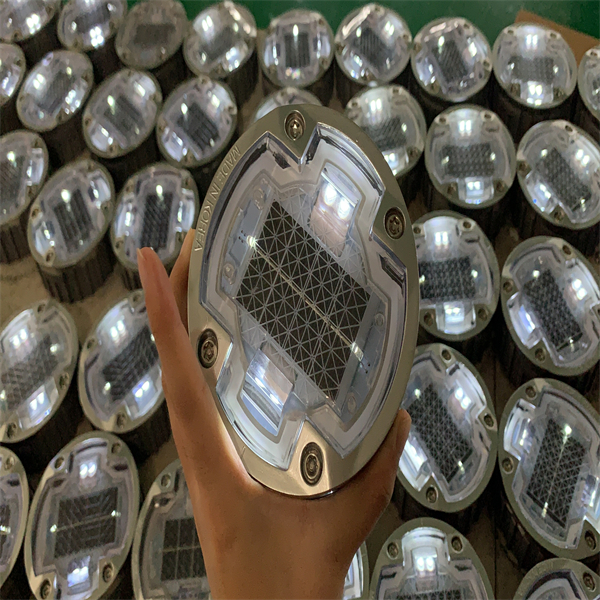

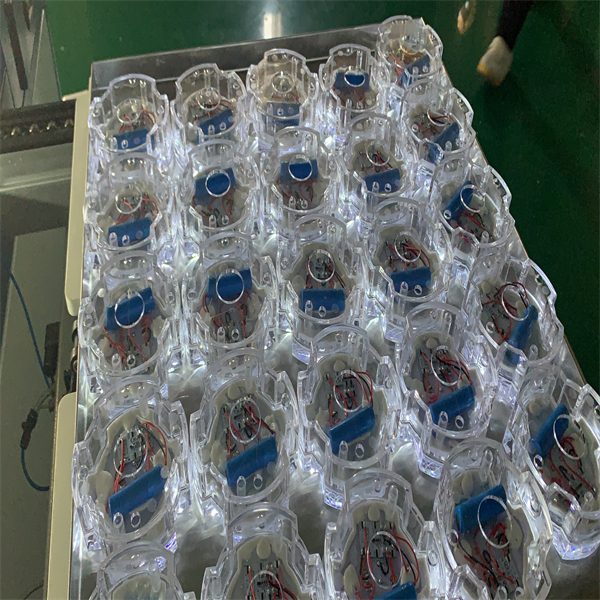

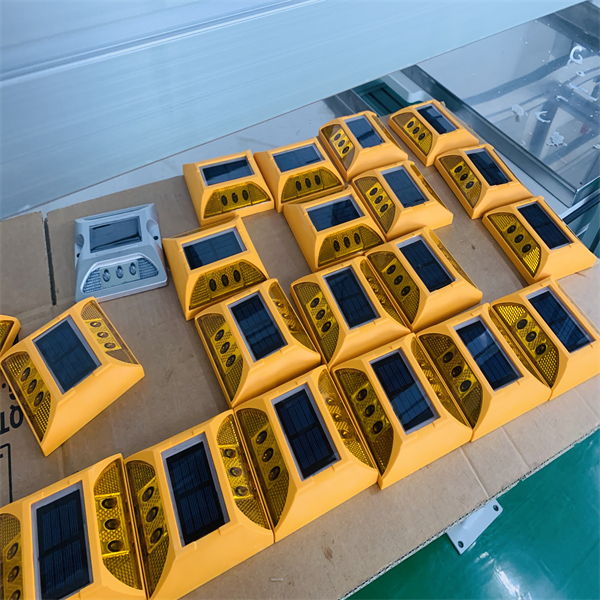

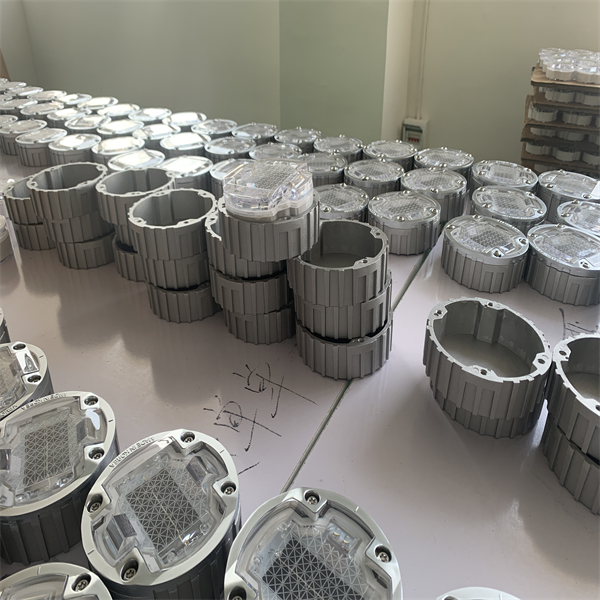

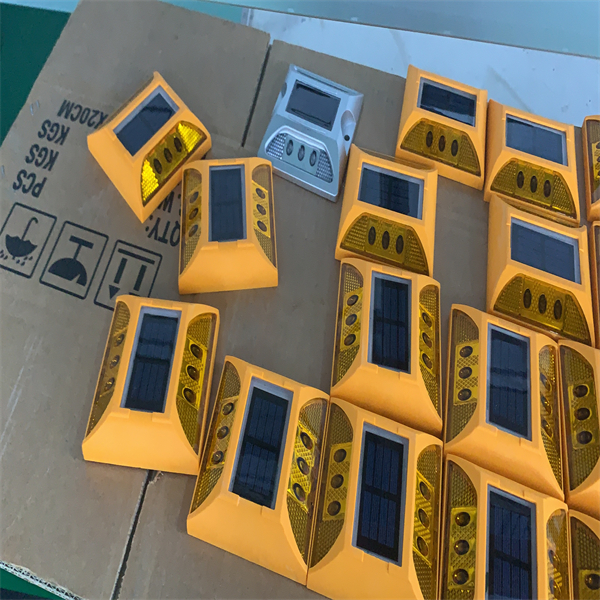

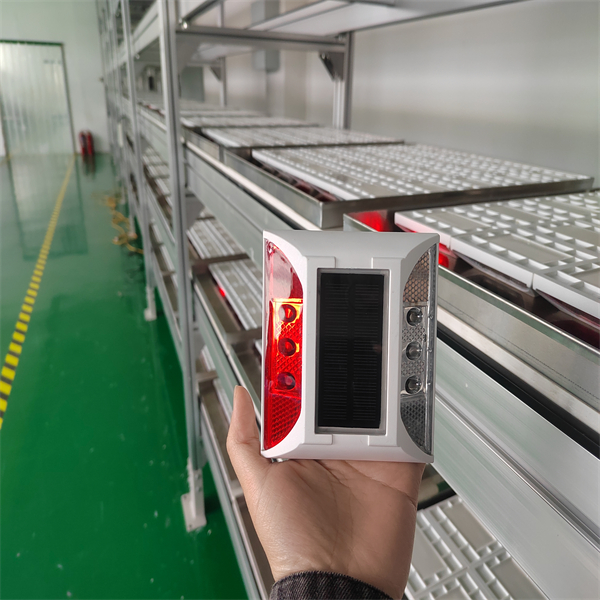

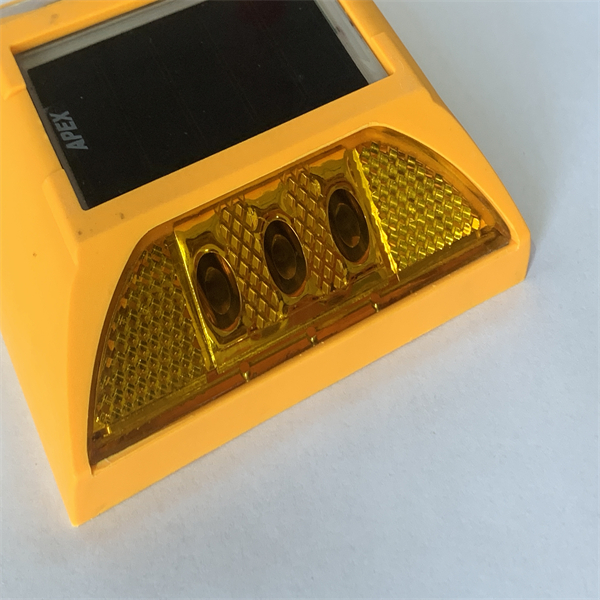

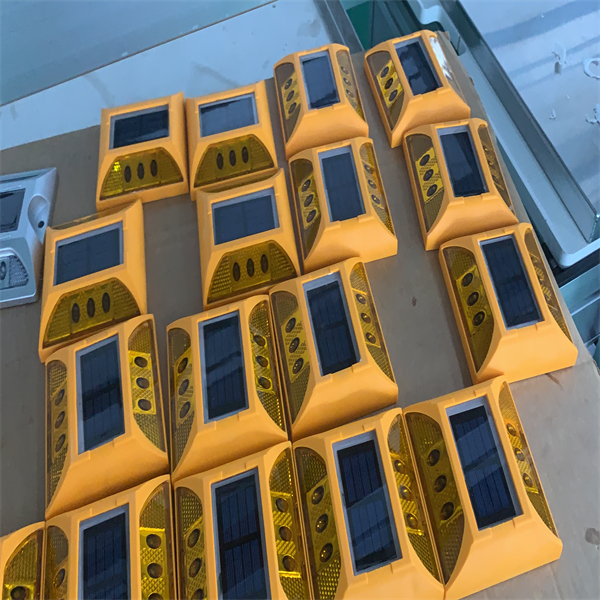

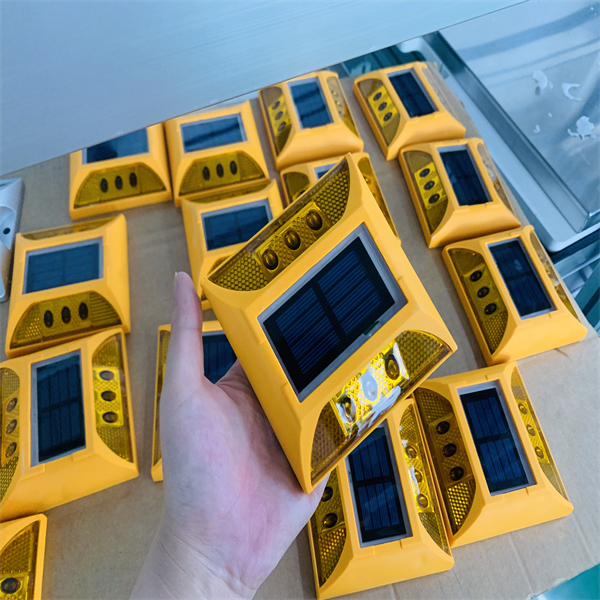

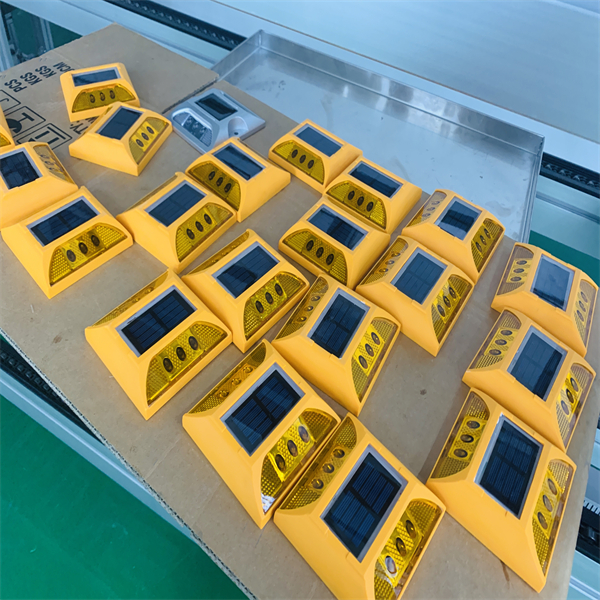

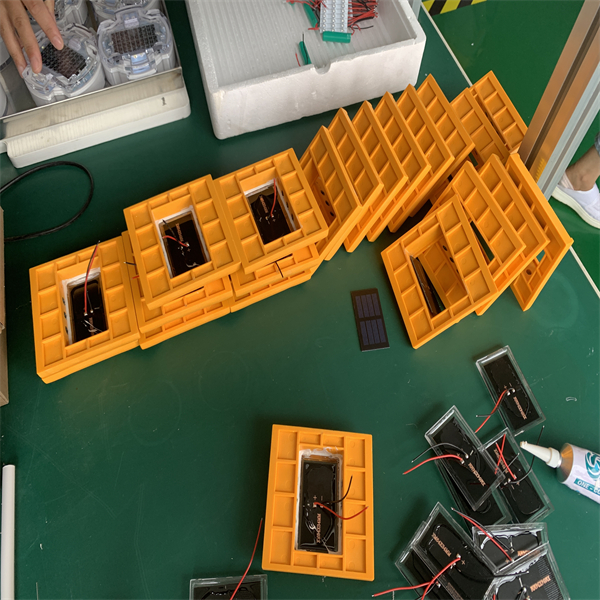

Improving the static compressive strength of Road Studs is mainly achieved by increasing the strength of Road Studs material. At present, the Road Studs sold in the domestic market are divided into metal material Road Studs (such as aluminum Road Studs), engineering plastic material Road Studs (such as engineering plastic Road Studs made of polycarbonate, polyacrylic acid, etc.) and mixed materials. Road Studs (such as Road Studs with engineering plastic shell + quartz sand filling). Among them, Road Studs made of metal have the highest compressive strength, followed by Road Studs made of engineering plastics and mixed materials.

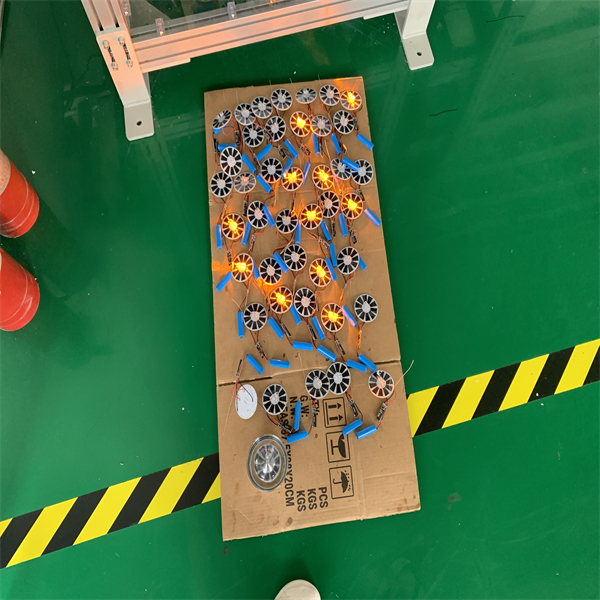

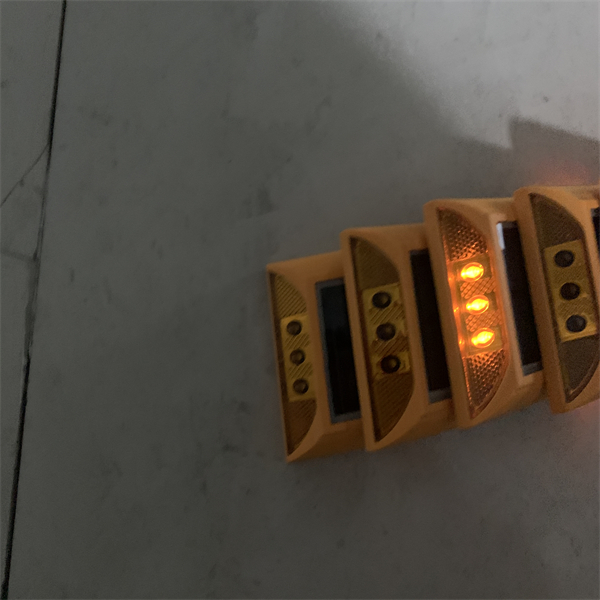

The damage to the Road Studs is mainly due to the insufficient strength of the materials used in the Road Studs. Road Studs will be subjected to static pressure load and impact load during actual use. The static pressure load is mainly formed by the tires pressing on the Road Studs when the vehicle is stationary; the impact load is mainly generated when the tires run over the road studs while the vehicle is running.

Improving the static compressive strength of Road Studs is mainly achieved by increasing the strength of Road Studs material. At present, the Road Studs sold in the domestic market are divided into metal material Road Studs (such as aluminum Road Studs), engineering plastic material Road Studs (such as engineering plastic Road Studs made of polycarbonate, polyacrylic acid, etc.) and mixed materials. Road Studs (such as Road Studs with engineering plastic shell + quartz sand filling). Among them, Road Studs made of metal have the highest compressive strength, followed by Road Studs made of engineering plastics and mixed materials.

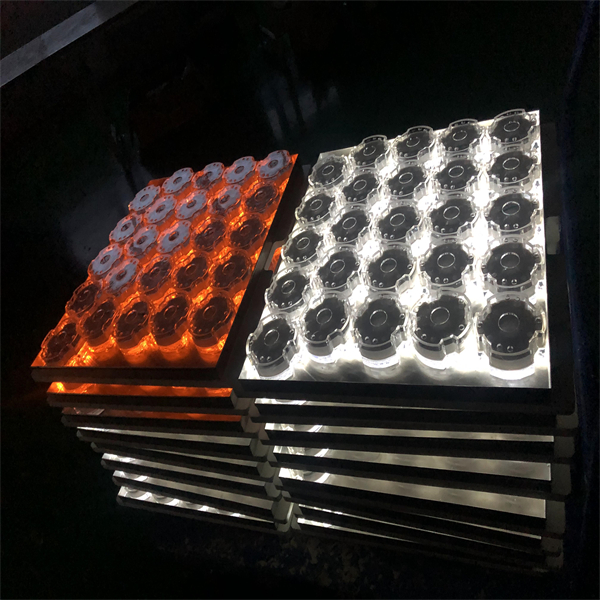

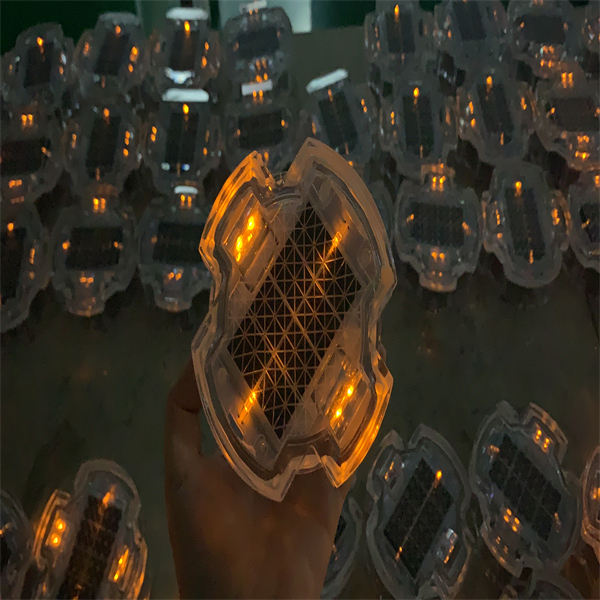

Improving the impact strength of Solar Road Studs can also be achieved by increasing the strength of Solar Road Studs. In terms of materials, metal materials have the highest impact strength, followed by engineering plastic materials, and mixed materials have the lowest impact strength (due to different deformation coefficients of different materials).

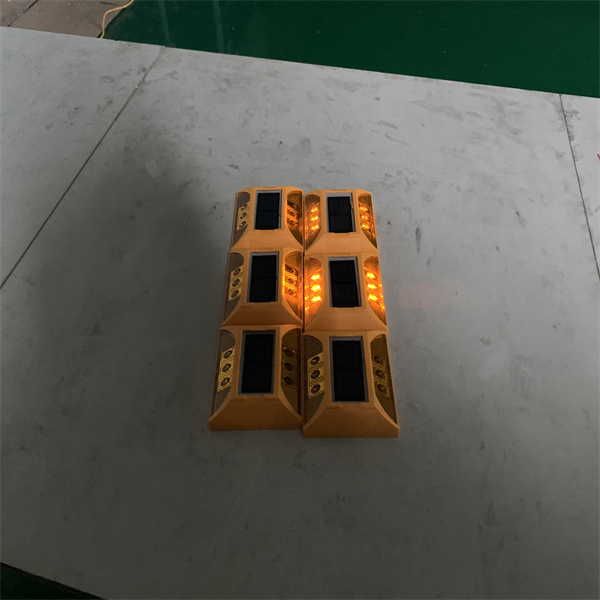

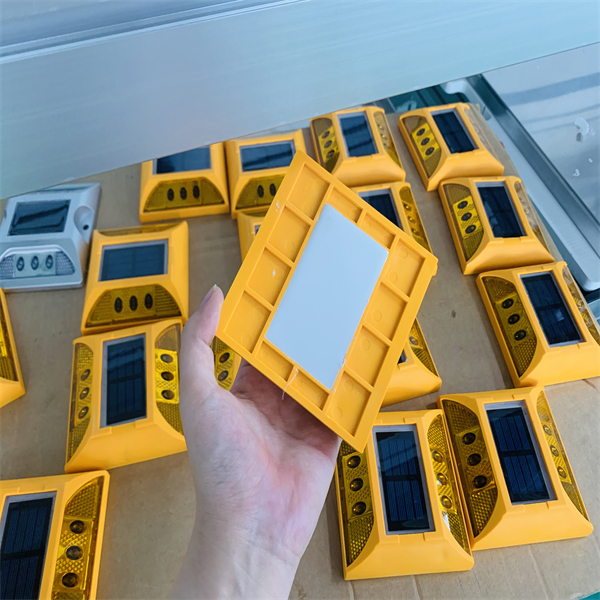

Solar Road Studs and the ground rubber//the road surface breaks away from the bottom and the reason is that the lateral shear force parallel to the road surface generated when the wheel runs over the spike is greater than the binding force of the Solar Road Studs and the road surface. Therefore, it is particularly important to choose different types of primers for different pavements. For asphalt pavements, asphalt glue has the best bonding effect, and for cement pavements, epoxy resin has the best bonding effect. In addition, by optimizing the shape of Solar Road Studs, the lateral shear on spikes can be reduced.

Shear force or strengthen the effect of the bonding strength of Solar Road Studs and the road surface. For example, the Solar Road Studs with feet (the feet of the Solar Road Studs are inserted vertically into the ground during installation) can increase the bonding strength of the Solar Road Studs and the road surface; reduce the reflective surface of the Solar Road Studs and the bottom surface of the Solar Road Studs (that is, the reflective surface of the Solar Road Studs and the bottom surface of the Solar Road Studs). The included angle of the road surface can reduce the lateral shear force of Solar Road Studs. It can be seen from the force analysis of Solar Road Studs that the smaller the angle, the smaller the lateral shear force that Solar Road Studs bear, and the greater the vertical pressure.